Introduction

In the contemporary landscape of environmental sustainability, the recycling of agricultural waste emerges as a critical facet in waste management. This article delves into the intricacies of one such method – charcoal making. From its historical evolution to the modern precision of advanced machines, we explore the transformative potential of converting agricultural residues such as straw, rice husk, and jute stick into valuable charcoal.

Key Agricultural Residues

Exploring the Potential of Straw

Traditionally seen as mere remnants of grain harvesting, straw is redefining its role in agriculture. Its fibrous structure, rich in cellulose, makes it an ideal candidate for advanced charcoal making. This section unravels the layers of potential within straw, turning what was once considered waste into a valuable resource.

Harnessing Energy from Rice Husk

In regions abundant with rice cultivation, the sheer volume of rice husk generated presents an untapped reservoir of energy. Recognized for its high calorific value and silica-rich composition, rice husk takes center stage in the realm of advanced charcoal making. We delve into the unique attributes that make rice husk a valuable feedstock in this process.

Jute Stick’s Role in Lignocellulosic Transformation

Agricultural residues, often overlooked, include the lignocellulosic marvel – jute stick. This section explores the intricate composition of jute stick and how advanced charcoal making machines tailor their processes to extract maximum value. From overlooked remnants to a key player in sustainable waste management, jute stick’s journey is unveiled.

Advanced Charcoal Making Machines

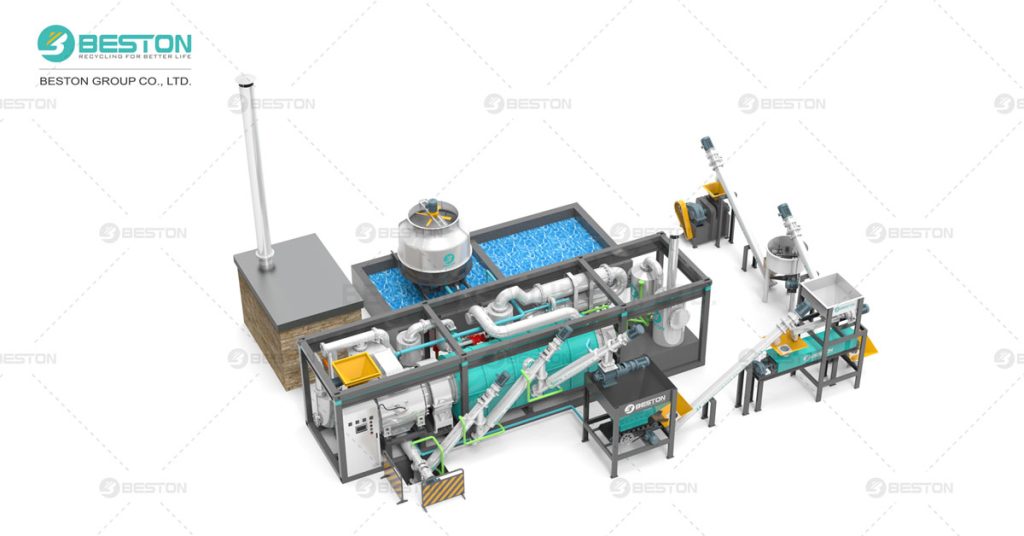

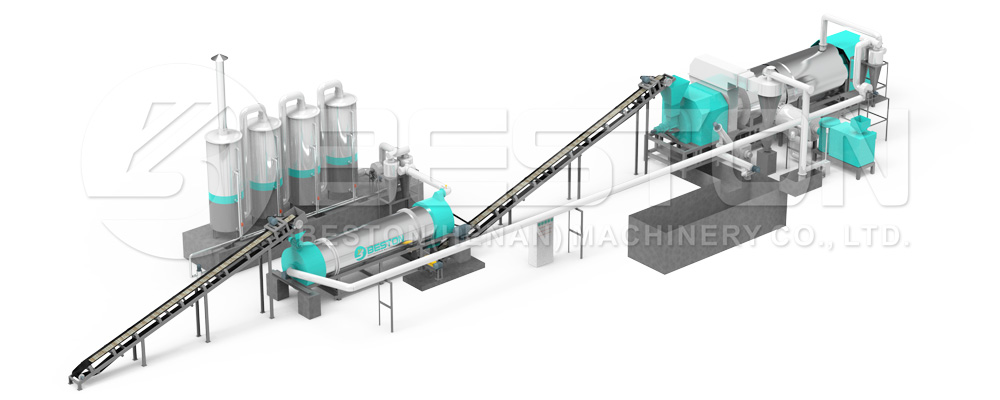

Precision in Charcoal Production

At the heart of this transformative process lies the advanced charcoal making machine. This section delves into the technological precision of these machines, orchestrating the controlled conversion of agricultural residues into high-quality charcoal. The marriage of engineering and agriculture unfolds in a symphony of efficiency.

The Straw Charcoal Machine: A Focus on Efficiency

Tailored for the unique characteristics of straw, the straw charcoal machine optimizes the pyrolysis process. Efficiency takes the forefront as this specialized apparatus ensures maximal yield while minimizing energy consumption. The intricate dance between technology and agricultural residue sets a benchmark for precision in waste recycling.

Optimizing Energy Output with Rice Husk Charcoal Machine

For the copious amounts of rice husk awaiting purposeful utilization, the rice husk charcoal machine emerges as a game-changer. This section explores how these machines are designed to accommodate the specific traits of rice husk, extracting maximum energy output while adhering to the principles of sustainability and environmental responsibility.

Crafting Value from Lignocellulose: Jute Stick Charcoal Machine

In the intricate dance of agricultural waste transformation, the jute stick charcoal machine takes center stage. Engineered to navigate the complex lignocellulosic structure of jute stick, this machine ensures that no potential energy remains untapped. The section explores how this technological marvel contributes to the circular economy.

Pyrolysis Process

Pyrolysis Unveiled: Chemical Symphony

The essence of charcoal making lies in the pyrolysis process. This section unveils the chemical symphony as straw, rice husk, and jute stick undergo controlled heating. Cellulose, hemicellulose, and lignin break down meticulously, giving rise to a carbon-rich residue – the coveted charcoal. Precision in pyrolysis defines the quality of the end product.

Temperature Dynamics: The Crucial Control in Charcoal Making

Temperature control within the biomass pyrolysis plant is not merely a detail but a crucial determinant of the end product’s quality. This section explores the delicate balance of heat required to ensure the optimal degradation of organic compounds. From controlled temperatures to desirable charcoal characteristics, every degree plays a role in this intricate process.

Environmental Impact

Carbon Neutrality: A Green Footprint

Beyond the intricacies of machinery and pyrolysis, the environmental impact of charcoal making from agricultural waste cannot be overstated. This section explores how the resulting charcoal, when used as a fuel source, maintains a near carbon-neutral footprint. This contribution aligns with global efforts to combat climate change through sustainable waste utilization.

Economic Viability: Turning Waste into Wealth

The economic viability of advanced charcoal making machines lies not only in waste reduction but also in the creation of a new revenue stream. This section delves into how agricultural residues, once considered liabilities, are now valuable commodities. The transformation from waste to wealth marks a paradigm shift in resource utilization.

Challenges in Charcoal Making

Technical Challenges: Fine-Tuning Precision

While these advanced machines represent a remarkable leap forward in agricultural waste recycling, technical challenges persist. This section explores the ongoing frontier of fine-tuning the intricacies of charcoal making machines, especially when dealing with diverse feedstock compositions. Precision in technology becomes a key aspect of maximizing efficiency.

Market Dynamics: Bridging Traditional Practices and Innovation

The acceptance and widespread adoption of advanced charcoal making machines hinge on cultivating awareness within the market. This section discusses the challenges of bridging the gap between traditional agricultural practices and innovative waste recycling solutions. Strategic interventions are necessary to highlight the economic, environmental, and operational benefits. Therefore, it is particularly critical to find a reliable charcoal making machine manufacturer. Here is a suggestion to make Beston Group your first choice.

Future Prospects

Advancing Precision in Charcoal Making

As technology continues to evolve, this section explores the future prospects of advancing precision in charcoal making. Fine-tuning machines to accommodate variations in feedstock composition and ensuring optimal efficiency remain areas of ongoing research and development. The quest for precision paves the way for a more impactful role of charcoal making in waste recycling.

Cultivating Awareness for Market Acceptance

Market acceptance is pivotal for the success of any sustainable initiative. This section discusses the future prospects of cultivating awareness about advanced charcoal making methods. Fostering a widespread understanding of the benefits and overcoming traditional preferences for conventional energy sources are challenges that require strategic interventions for broader market acceptance.

Conclusion

In recapitulation, this article has traversed the landscape of agricultural waste recycling methods, focusing on the intricate process of charcoal making. From the overlooked residues of straw, rice husk, and jute stick to the precision of advanced machines, the transformative journey towards sustainable waste management has been unveiled. As we stand on the cusp of a new era, the amalgamation of technology and nature in charcoal making signifies a paradigm shift towards a more sustainable future.