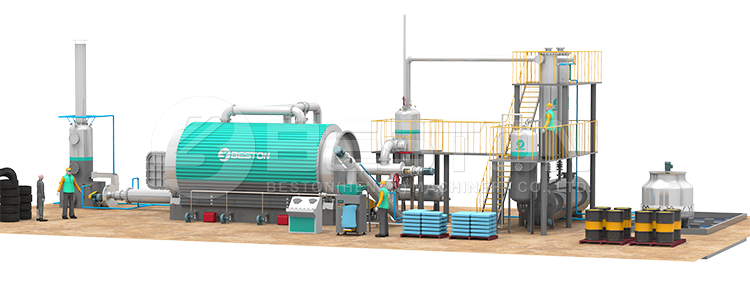

A waste tire pyrolysis machine is a machine that is designed for converting waste tires, and other raw materials, into steel wire, carbon black, fuel oil, and combustible gas via the pyrolysis process. Some of the other types of raw materials that can be fed into such a machine include waste plastic, oil sludge, and wood. Obviously, steel wire is only produced when scrape tires are processed as there is no steel in waste plastic, and the other raw materials mentioned.

There are various different types of waste tire pyrolysis machines, and they are typically classified by their working method. The three main types are batch operating plants, semi-continuous machines, and fully continuous plants. As you can probably deduce from its name, a fully continuous waste tire pyrolysis machine can operate 24 hours a day, seven days a week. Before looking for pyrolysis equipment for sale, it’s vital that investors understand what type of machinery they are looking for.

End Products

As mentioned at the start of this article, the four end products produced by a waste tire pyrolysis machine are steel wire, carbon black, combustible gas, and fuel oil. The fuel oil produced can be used to power many different types of machinery, but to increase its value in the global marketplace, many waste tire pyrolysis machine operators carry out further distillation on the fuel oil.

The 50-60 mesh carbon black produced by a pyrolysis machine is a profitable commodity in its own right, but it can also be processed further into 325+ mesh carbon black. There is a big market for any type of carbon black, especially in the plastic and rubber industries, where it is used as a filler, colorant and/or fortifier.

Steel wires are easy to sell to the metal industry. For plant operators wishing to prolong the service life of their rubber pyrolysis machines, it’s vital that all steel wire is removed from waste tires before they enter the reactor.

The combustible gas produced during the pyrolysis process in a waste tire recycling facility is typically reused onsite to reduce energy costs. Some of the best continuous waste tire pyrolysis machines are engineered with systems that can automatically recycle the combustible gas produced and use it to heat the reactor.

Profitable Recycling Processing Plant

The main reason people invest in waste tire pyrolysis machines is that there is a lot of money to be made in the recycling industry in many countries. The disposal of waste tires and waste plastic is a mounting problem in many cities around the world, and the need for scrap tire processing plants has never been greater. The great thing about the pyrolysis process is that unlike the incineration process, no toxic emissions are produced.