Why would you want to have a tyre to oil plant? Well, it’s not just about energy savings and environmental protection, but it’s also a cost-effective solution for the oil industry. But what exactly is the process of converting waste tyres into oil? Let’s find out! Continue reading for more information! This article will show you how to set up a tyre to oil plant in just a few simple steps.

Energy Saving

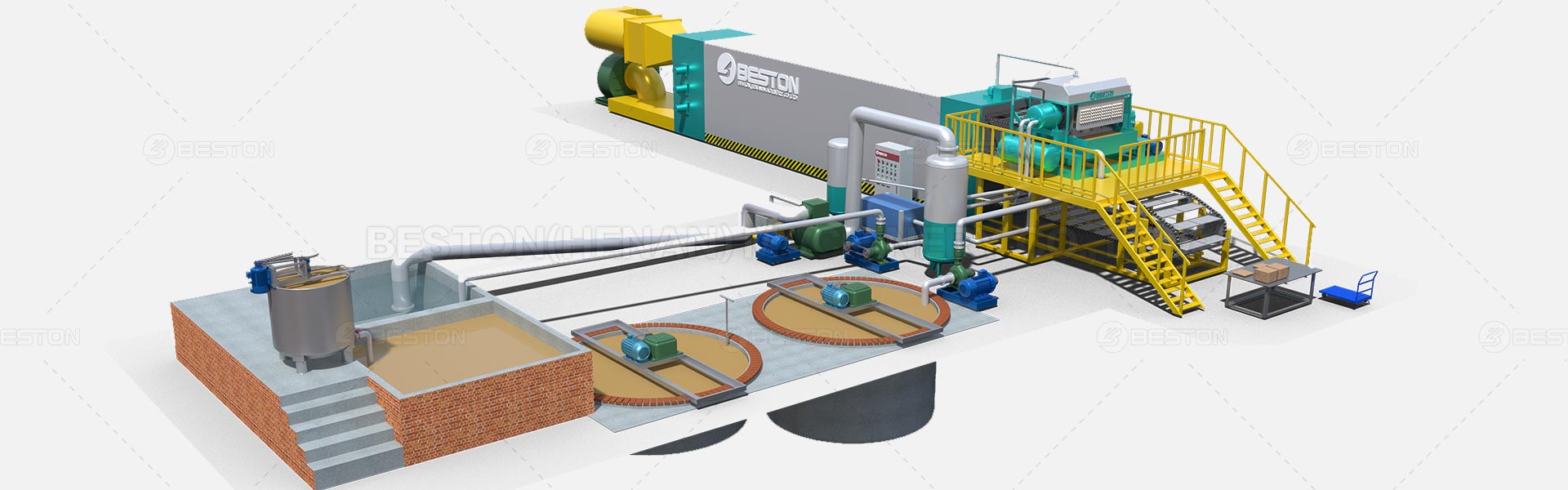

The process of converting waste tires into useful energy is called tyre to oil. The process produces 45% fuel oil, 35% carbon black, 12% steel wire, and 8% combustible gas. Fuel oil is a useful fuel in the industrial world, can be refined into diesel, and carbon black can be recycled into chemicals. Steel wire is recyclable, can be resold, or can be used in steel plants. Combustible gas can be used for industrial processes or as a feedstock for agricultural, industrial, and other uses.

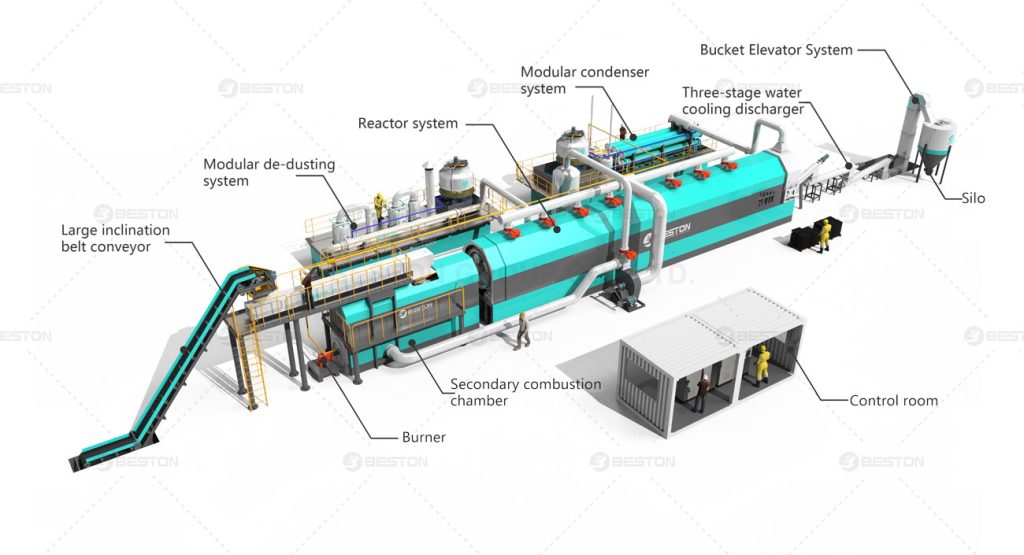

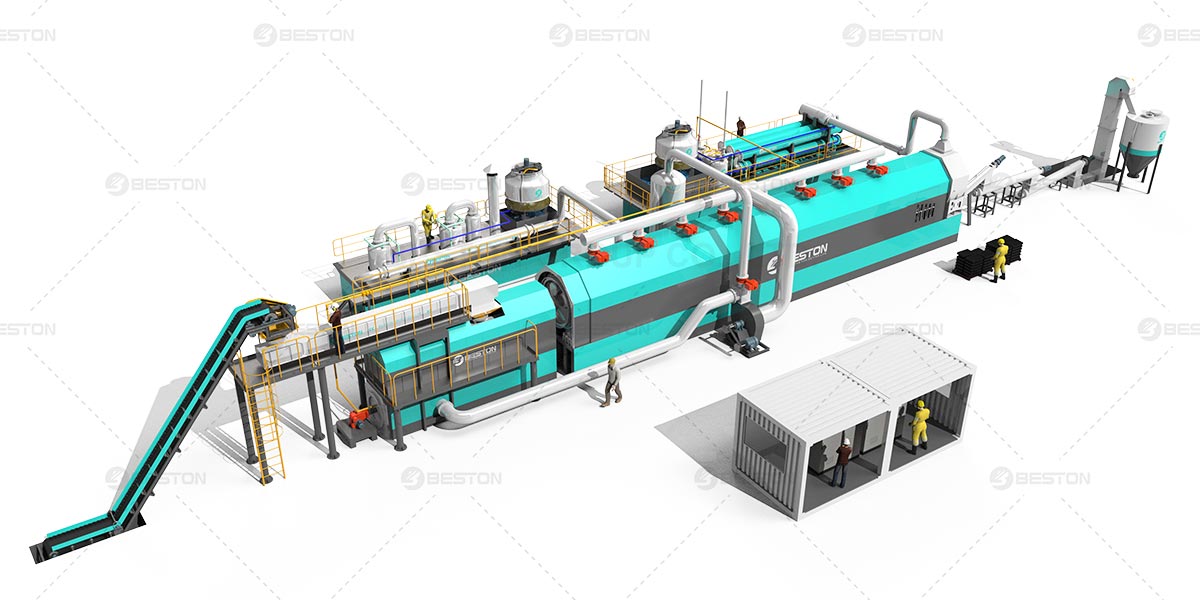

Beston tyre to oil plant utilizes innovative heating structure, combining hot-wind and directly heating the process. This technology extends service life, improves productivity, and reduces costs. The small pyrolysis machine is also protected from excessive temperatures by a casing outside the reactor. This casing is a key component in preventing fire from contaminating the oil produced in the process.

Environmental Protection

In recent years, the environmental protection has become more important than ever, with more countries passing stricter environmental standards. With more countries introducing stricter environmental protection standards, tyre to oil plants that adhere to these rules are likely to find an expanded market. Environmental protection is the first element of any tyre to oil project, so the state is encouraging and supporting environmentally responsible enterprises. To protect the environment, the waste tyre to oil plant has undergone a complete enclosure. Besides emitting white smoke and no smell, the pyrolysis plant also produces very high levels of carbon dioxide, nitrogen oxides, and other pollutants.

The process also produces useful materials, such as 45% fuel oil, 35% carbon black, 12% steel wire, and 8% combustible gas. These byproducts can be used as industrial fuel or refined to diesel, while the steel wire can be recycled to steel plants or sold. Finally, the combustible gas can be reused as fuel in a reactor, saving energy and money. More information on tyre pyrolysis plant here.

Cost Reduction

When determining cost reduction from tyre to oil plant, consider ongoing costs and total operating expenses. Running a tyre to oil plant is not cheap, but it can be lucrative as well. The following steps can help you achieve the lowest possible costs. In addition, consider the value retention metrics associated with tyre to oil processes. While a process that worked a few years ago is now obsolete and inefficient, there are a few important things to consider.

Choose an environmentally friendly process. Many companies that convert tyres into oil do not install the plants themselves, which means that they end up with a low yield rate. Invest in a tyre to oil plant that meets national standards. In addition, it can save you money on environmental taxes. Finally, consider your business’ needs. There are many benefits to operating a tyre to oil plant.

Process Of Converting Waste Tyres Into Oil

The process of converting waste tyres to oil has a number of advantages, including being clean and green, and avoiding environmental pollution. During the recycling process, waste tyres are reduced to a size of about 50mm, which is suitable for a batch-operating pyrolysis machine. After the waste tyres are inserted into the reactor, they are heated by fuel material (wood, gas, etc.) until they reach a temperature of 120 degrees Fahrenheit. This heat transforms into oil gas.

The resulting oil can be processed into fuels, such as diesel and gasoline. The refined oil can be used to fuel a heavy oil generator. It can also be used to generate electricity. The process also yields carbon black, which can be further processed and sold for fuel or recycled to steel plants. Combustible gas can be used as fuel to heat a reactor, reducing energy costs.