It’s a smart idea to get the best waste tire recycling plant for sale instead of something that isn’t a good deal. Some options are going to be worth it and some are going to be unfair. This means that you’re going to need to read on to get an idea of what to spend money on.

Know what is worth the price and what some companies(Beston Grupo de China) are charging a lot more for than what something is worth. If you’re not careful, you can end up paying quite a high price only to find out later that you could’ve gotten a much better deal if you did a bit of shopping around at first. You will benefit from learning what a couple of companies, at the least, want to charge. That way, you can figure out what an average price is and can avoid people that are price gouging.

To save a bit of money, it’s possible to work with a company that is having a sale of some kind. Also, when checking out on a website you’re buying something from, see if there’s a box where you can put in a coupon code. That way, you can stop the checkout process for a minute to see if you can find a code that will help you save a bit of money on the purchase. If you can’t find any deals for what you’re buying it(planta de pirolisis de neumaticos) doesn’t hurt to contact the company to see if they can provide you with a better deal.

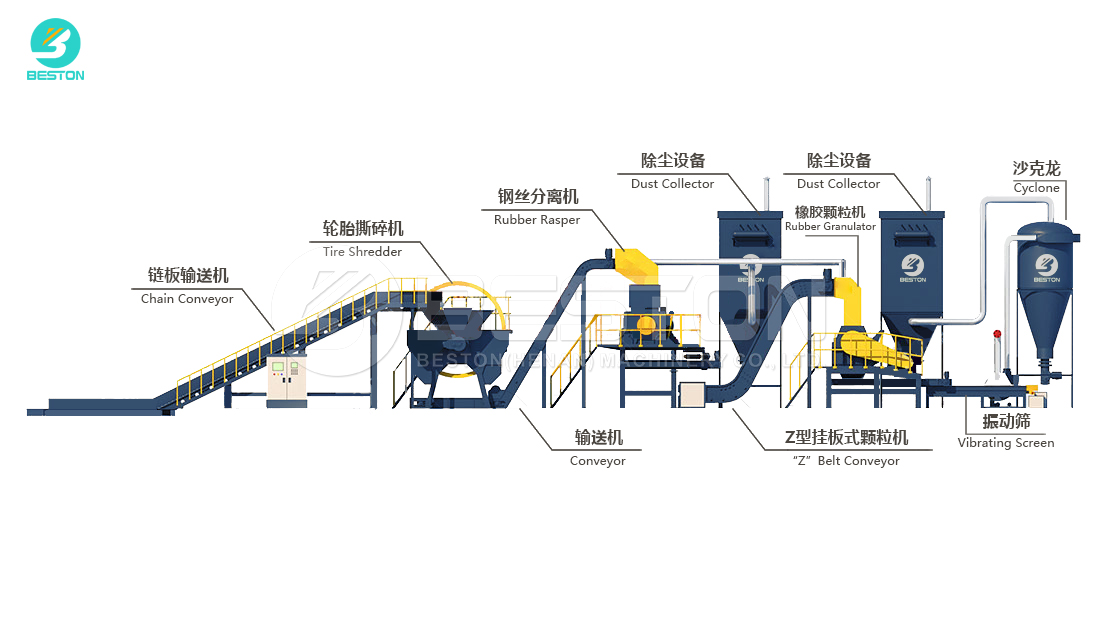

Read up on how to run your new waste tire recycling plant before you start working with it. If you don’t know what you’re doing, that’s a quick way to ruin your new plant and cause yourself to waste money in the process because you’ll have to buy a new one when you break what you have. Generally, you can find instructions on how to run something by searching for them online. Just make sure you’re reading a manual that is about the exact make and model(https://www.bestoneco.com/venta-de-planta-de-pirolisis/) of what you’re buying so you know the information applies.

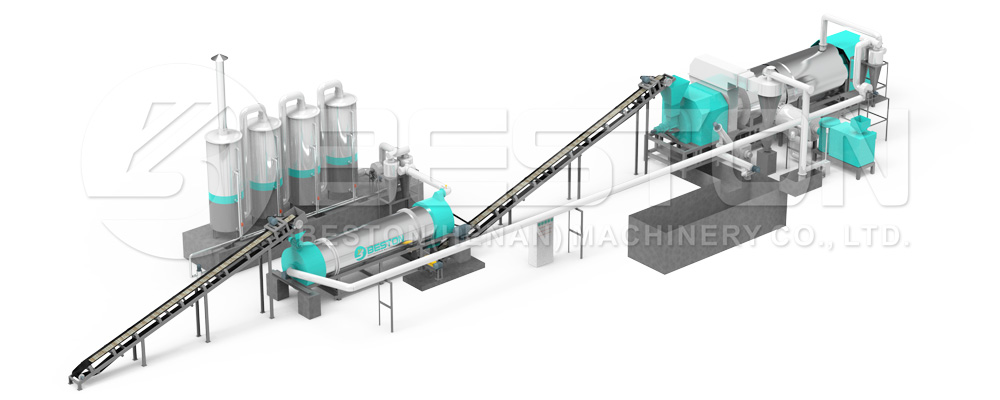

If you’re going to buy something that has been worked with in the past to see if you can save as much as possible, insist that the company at least sends you photos of the recycling plant(planta de reciclaje de neumaticos). That way, if it’s in bad shape you can tell and can avoid spending anything on it. The best thing to do is see if you can check it out in person if it’s being sold around where you live. When you can do that, you can find out exactly what kind of shape something is in to avoid spending anything on what doesn’t work well.

Once you find the right waste tire recycling plant for sale, you can know it’ll be worth the investment. There are going to be a few different choices out there so be sure you use what you got information on above to figure out what it is that will be a good purchase.