The charcoal making machine market has witnessed significant growth in recent years, driven by rising environmental concerns, increased demand for sustainable energy sources, and advancements in pyrolysis technology. The industry is adapting to global sustainability efforts, where biochar production units play a pivotal role. With an emphasis on carbon sequestration and soil enhancement, the potential applications of charcoal extend far beyond traditional uses. This article explores key trends and insights shaping the charcoal production sector, highlighting emerging markets such as Malaysia and Turkey.

Market Overview

Charcoal production, once a labor-intensive process, has evolved into a technologically advanced industry. The introduction of modern charcoal making machines has optimized efficiency, lowered production costs, and improved the overall quality of the product. The increasing need for biochar, a byproduct of charcoal, has led to the development of more specialized biochar production units. These units not only produce charcoal but also facilitate environmental benefits by capturing carbon from organic waste and converting it into a stable form that can be used for soil improvement.

Regional Insights: Malaysia and Turkey

In countries such as Malaysia and Turkey, the demand for charcoal making machines is growing due to both domestic consumption and export opportunities. Charcoal making machine in Malaysia has gained traction, with increasing awareness of the need for sustainable waste management solutions. The demand for charcoal for use in various industries, including agriculture and energy, has propelled the growth of the market in this region. Malaysia’s strategic location within Southeast Asia also offers an advantageous trade environment for the export of charcoal products.

In Turkey, charcoal making machine in Turkey has similarly seen increased adoption. As a country with a robust agricultural sector, Turkey presents significant opportunities for biochar production, particularly in soil improvement and sustainable farming practices. The use of charcoal in agricultural applications has created a niche market that continues to expand, with manufacturers responding to this trend by offering specialized machinery for biochar production.

Key Drivers of Market Growth

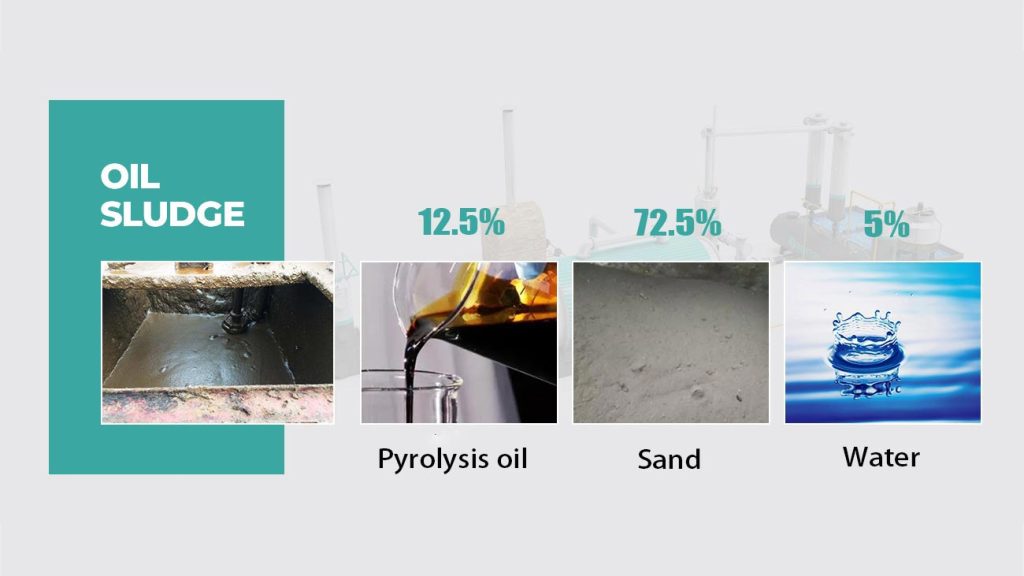

Several factors contribute to the growth of the charcoal making machine market. One of the primary drivers is the increasing awareness of environmental issues such as deforestation, climate change, and waste management. As industries seek to reduce their carbon footprint, biochar production units have become a key solution. By converting organic waste into a stable form of carbon, these units help mitigate harmful greenhouse gas emissions and provide valuable soil amendments.

Additionally, the rising demand for charcoal machine price transparency has encouraged competition in the market. With numerous manufacturers offering a wide range of products, buyers are more informed than ever about their options. Lower prices combined with improved machine capabilities make it easier for both small-scale and large-scale producers to invest in charcoal production technology.

Technological Advancements and Innovations

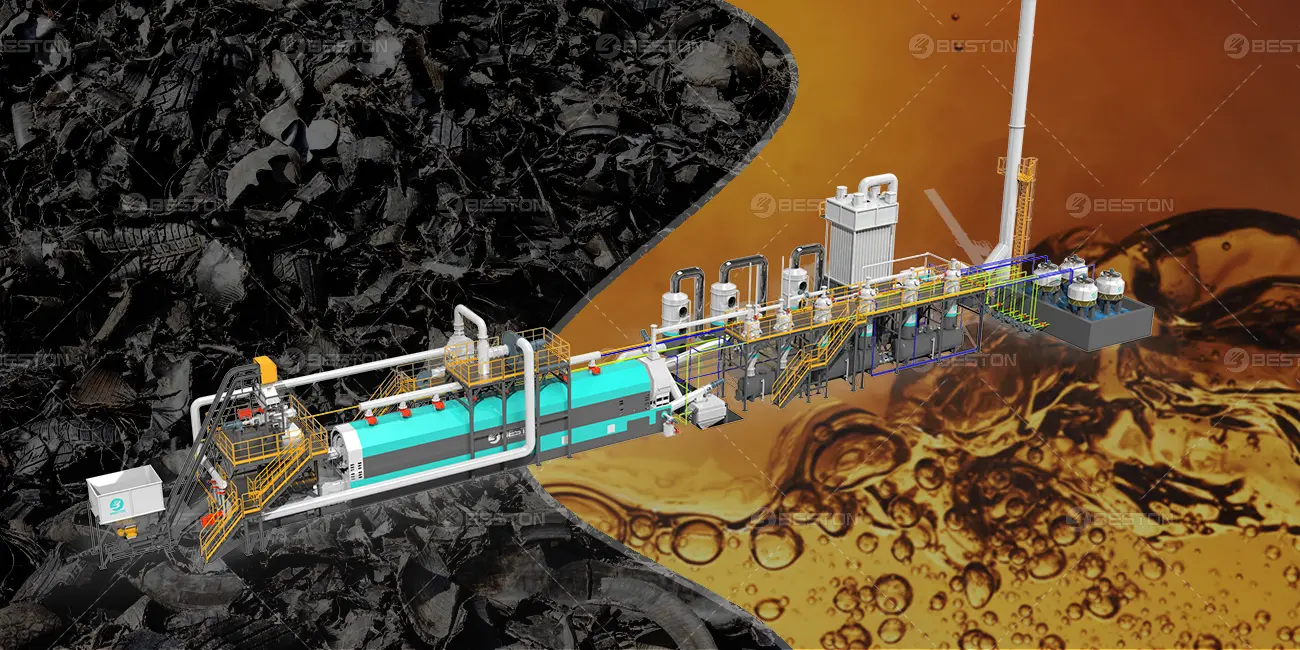

Innovations in pyrolysis technology have revolutionized the charcoal making industry. Modern charcoal making machine in Turkey now incorporate advanced features such as automated feeding systems, energy recovery mechanisms, and integrated cooling technologies. These innovations not only enhance the efficiency of the production process but also improve safety standards and reduce the environmental impact of charcoal making.

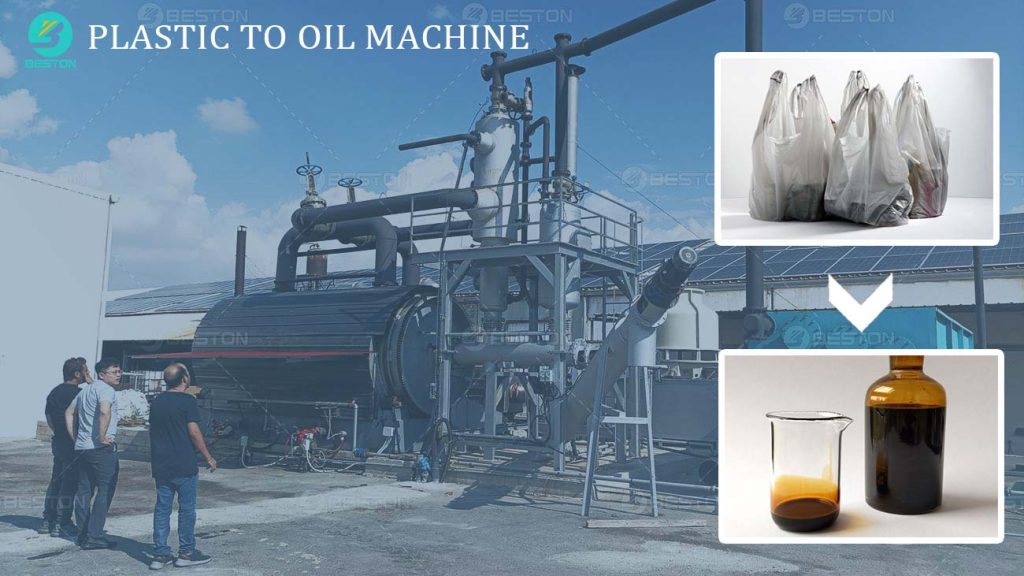

The ability to process a wide variety of raw materials—such as agricultural waste, wood chips, and even plastics—further strengthens the versatility of charcoal machines. These machines offer significant advantages, including reduced operating costs and the ability to produce high-quality biochar, which is a valuable product for soil amendment and carbon sequestration.

Conclusion

The charcoal making machine market is poised for continued growth, driven by technological innovations, increasing environmental awareness, and the demand for sustainable production methods. The expansion of biochar production units is helping industries meet environmental goals while addressing global waste management challenges. Countries like Malaysia and Turkey are emerging as key players in this market, benefiting from their agricultural sectors and the growing need for energy-efficient, eco-friendly charcoal production solutions. As technological advancements continue to shape the industry, the future of charcoal production looks promising, offering both environmental and economic benefits.