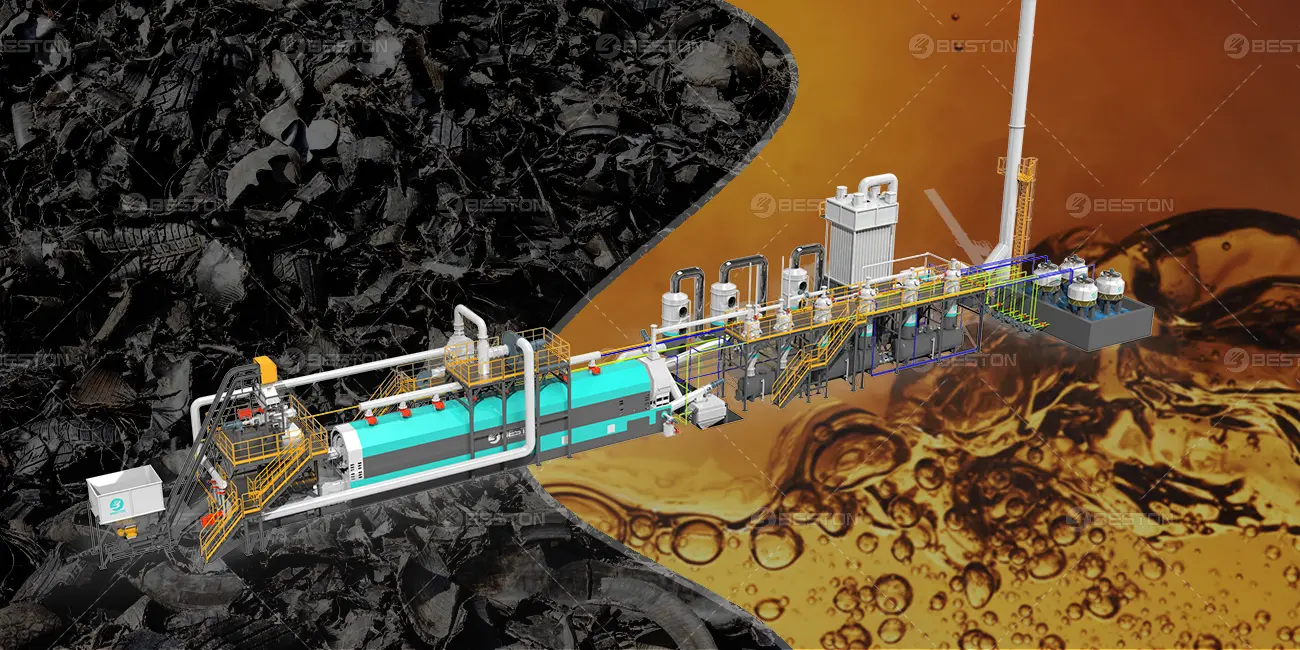

The demand for sustainable waste management solutions has led to the proliferation of tire pyrolysis plants. These facilities are designed to convert end-of-life tires into valuable by-products such as oil, carbon black, and steel wire. While the environmental and economic advantages of tire pyrolysis are significant, the financial viability of such an investment hinges on a detailed cost analysis. A thorough understanding of the various factors that contribute to the pyrolysis plant cost is essential for businesses considering this technology.

Initial Capital Investment

The primary tire pyrolysis plant cost associated with establishing a tire pyrolysis plant is the initial capital investment. This includes the purchase of the pyrolysis reactor, auxiliary equipment such as condensing systems, material handling systems, and air pollution control devices. Additionally, expenses for land acquisition, facility construction, and site preparation can further elevate the initial investment.

The scale of the plant plays a pivotal role in determining the overall capital expenditure. Larger plants capable of processing higher volumes of tires typically require more expensive machinery and more extensive infrastructure. While the upfront costs are substantial, the return on investment (ROI) can be significant if the plant is designed to operate at maximum capacity for extended periods.

Operational Costs

Once the plant is established, ongoing operational costs must be factored into the financial analysis. The key operational costs include raw material procurement, labor, maintenance, utilities, and waste disposal.

-

- Raw Material Procurement: The main raw material for tire pyrolysis reactor is used tires, which are generally inexpensive but can fluctuate in price based on market demand and regional availability. Some plants may have contracts with tire suppliers, which can help stabilize costs. However, sourcing a consistent and affordable supply of tires is crucial for maintaining profitability.

- Labor: Staffing requirements will vary based on the size and automation level of the plant. Small-scale operations may require fewer personnel, while larger, more complex plants will necessitate a skilled workforce. Labor costs should account for operators, technicians, and maintenance staff. Automation can reduce labor costs but often comes with higher initial capital costs.

- Maintenance: Regular maintenance of the pyrolysis reactor and associated systems is essential to ensure optimal performance and prevent costly downtimes. Routine inspections, part replacements, and repairs are part of the ongoing operational costs. The complexity of the machinery and the materials processed can influence the frequency and cost of maintenance.

- Utilities: Pyrolysis is an energy-intensive process, and the consumption of fuel and electricity can account for a significant portion of the operational costs. Some plants utilize the by-products of the pyrolysis process, such as oil and gas, to power the system, which can offset utility expenses. However, the overall energy requirements still need to be carefully managed.

- Waste Disposal: Even though tire pyrolysis reduces waste significantly, some residual materials, such as unconverted carbon black or non-condensable gases, must be properly disposed of. Depending on local regulations, waste disposal costs may vary. In some cases, the sale of carbon black and other by-products can mitigate these costs.

By-Product Revenue

A major advantage of tire pyrolysis machine is the generation of valuable by-products, which can offset the plant’s operational costs. These by-products include:

- Pyrolysis Oil: The oil produced during the pyrolysis process has numerous applications, including use as a fuel in industrial boilers, power plants, or as a raw material in the chemical industry. The price of pyrolysis oil fluctuates depending on market conditions, but it remains one of the most significant revenue streams for tire pyrolysis plants.

- Carbon Black: The carbon black produced is widely used in the production of rubber, plastics, and paints. It can be sold as a high-quality material or processed further into different grades for specific applications. The demand for carbon black is influenced by global industrial needs, and its sale can provide substantial income for the plant.

- Steel Wire: Tires also contain steel wire, which can be recovered and sold to scrap metal dealers or recycled into new steel products. The value of this steel is subject to market fluctuations, but it remains an important by-product.

The revenue generated from these by-products is a crucial factor in determining the overall profitability of the pyrolysis plant. Higher product yields and favorable market prices can significantly reduce the payback period and increase the plant’s financial return.

ROI and Payback Period

The return on investment (ROI) for a tire pyrolysis machinery is influenced by several factors, including the plant’s scale, operating efficiency, and market conditions. In general, the ROI for tire pyrolysis plants is favorable due to the growing demand for sustainable waste management solutions and valuable by-products.

A key metric to evaluate is the payback period, which represents the time it takes for the plant to recover its initial investment. For most tire pyrolysis plants, the payback period ranges from 2 to 4 years, depending on the plant’s capacity and operational efficiency. Larger plants with higher production capacities typically offer shorter payback periods and greater profit potential. However, careful attention to operational costs and product quality is essential to ensure the projected financial return is realized.

Long-Term Financial Considerations

In addition to the initial investment and ongoing operational costs, there are other financial considerations to take into account when analyzing the cost-effectiveness of a tire pyrolysis plant:

- Regulatory Compliance: Tire pyrolysis plants are subject to local environmental regulations. Compliance with air quality standards, waste management policies, and emissions controls can result in additional costs for monitoring and maintaining compliance. Failure to meet regulatory requirements can lead to fines or forced shutdowns, which can be costly.

- Market Fluctuations: The prices of the by-products—such as oil, carbon black, and steel wire—are susceptible to market fluctuations. It is essential to have a diversified customer base and consider long-term contracts to stabilize revenue streams. Additionally, fluctuations in the cost of raw materials (used tires) should be closely monitored.

- Technological Upgrades: As the technology behind tire pyrolysis continues to evolve, upgrading equipment to improve efficiency and product quality may be necessary over time. While these upgrades come with an initial investment, they can lead to significant cost savings and enhanced profitability in the long run.

In conclusion, while the pyrolysis plant cost may seem substantial at the outset, the long-term financial benefits of a tire pyrolysis plant can make it a highly profitable investment. By carefully considering the capital investment, operational costs, by-product revenue, and ROI, businesses can assess the financial viability of this technology and position themselves to capitalize on the growing demand for sustainable waste management solutions.