When you are working together with rebar, and you are hoping to help make different bends within the metal, this could be virtually impossible without some sort of machinery. This is the reason so many individuals will make use of electric rebar bender for sale because of the capability to create different angles with the metal with simply the push of the mouse. Many of them are very inexpensive, those who are portable, whereas there are others which can be extremely expensive that will actually automate many of the process. Generally, you will discover a single individual that is running the appliance, holding the bar set up, allowing the rollers to advance to bend the metal in seconds.

How Can They Work?

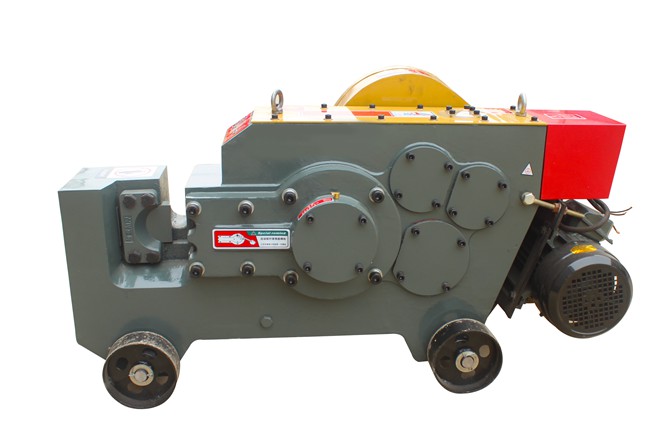

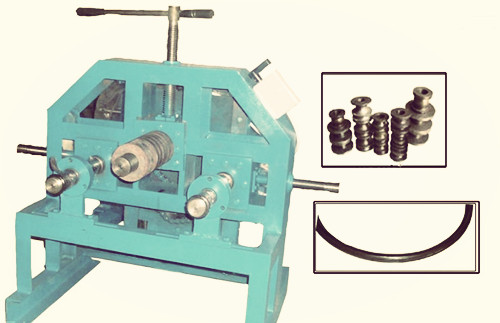

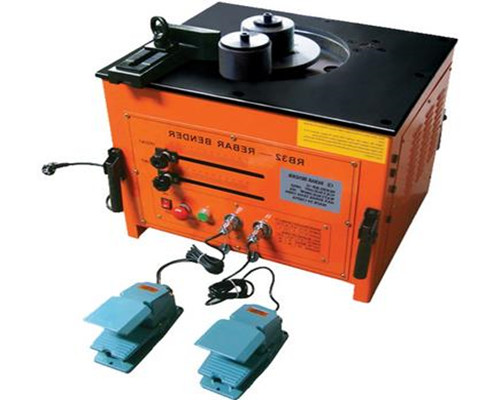

How does electric rebar bender work? They could do this work because of the way they can be constructed. There are actually vertical rollers on top that are capable of producing the bends. The worker holds the rod in just one location, in an exact point where they wish to bend to occur, along with the other roller will move to the side in a elliptical opening, bending it towards the proper angle. Most of these machines could be rolled two different areas. It’s very simple to truly use all of the devices. They will include an instruction manual, but there are actually usually just one or two buttons or switches for every single device simply because there is merely one job that these particular machines will do.

Where Are You Able To Get Them At A Discount?

You can actually get these to get a minimal amount of money provided that you know where you can purchase bender to bend rebar. The overseas companies that produce thousands of these annually will probably be your best choice for the lowest prices. This really is for new and used machines, but it is strongly advised that you simply spend the excess money for new things. This is a smart investment that will last for quite some time, and by obtaining the latest styles that are available, you can be assured you will have all of the modern capabilities that this latest electric bar bender for sale feature today.

Just How Long Can It Take To Get?

If you order steel rebar bender from Asia, and you live in America, by way of example, it may take few weeks to perform your order and possess it shipped in your location. Keep that in mind if you are sifting with the many that exist on the net. Even when you can place the order immediately, it may need some time to reach your facility.

Your choice for the electric rebar bender machine http://ellsenrebarbendingmachine.com/electric-rebar-bender-sale will probably be one that is affordable and definately will hold the capabilities that you are looking for. Most people will pick one that will do both round and ribbed rods, of numerous diameters, and most often have a motor speed of about 1400 revolutions each minute. A lot of the motors which can be electric are powered with about 3 kW, and you have a working disc diameter of roughly 350 mm. Every one of these components are standard with most of the smaller semiautomatic steel rod bending machines for bending bar #6, along with the fully automated ones if you choose to upgrade to something at that level.