In the quest for sustainable solutions to combat environmental degradation, pulp molding machines have emerged as pivotal technology in the production of eco-friendly tableware. As the world grapples with the adverse effects of plastic pollution, the demand for biodegradable and compostable products is surging. Pulp molding machines, designed to convert waste paper into durable, biodegradable tableware, offer a compelling alternative to traditional plastic and foam-based products. This article explores the multifaceted advantages of using a pulp molding machine for producing tableware, emphasizing its environmental, economic, and technological benefits.

Understanding Pulp Molding Technology

The Pulp Molding Process

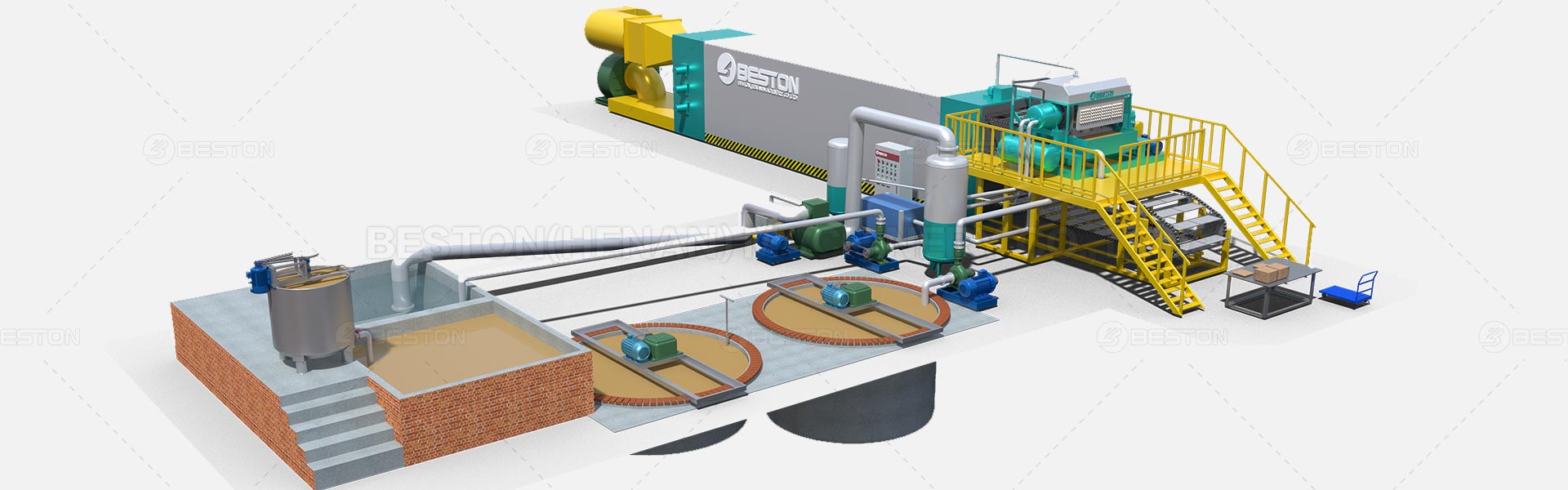

Beston pulp molding involves converting waste paper into various shapes and products using a specialized molding machine. The process can be broken down into several key stages:

-

- Pulp Preparation: Waste paper is collected and broken down into a slurry through the addition of water and chemicals. The slurry is then refined and cleaned to remove impurities.

- Molding: The prepared pulp is fed into a mold where it takes the desired shape. Vacuum suction and high pressure are applied to remove excess water, solidifying the shape of the product.

- Drying: The molded products are dried using thermal energy to evaporate any remaining moisture. This step ensures the products maintain their shape and structural integrity.

- Trimming and Finishing: The dried products are trimmed and polished to achieve the desired aesthetic and functional quality.

Key Products and Applications

Pulp molding machines are versatile and can produce a wide range of tableware products, including plates, bowls, cups, and trays. These products are highly sought after in various sectors, such as food service, catering, and retail, due to their biodegradability and environmental friendliness.

Environmental Advantages

Reduction of Plastic Waste

One of the most significant benefits of using pulp molding machine for tableware production is the reduction of plastic waste. Traditional plastic and foam-based tableware contribute significantly to environmental pollution, taking hundreds of years to decompose. In contrast, pulp-molded products are biodegradable and compostable, breaking down naturally in a matter of months. By replacing plastic with pulp-based products, businesses and consumers can significantly reduce their ecological footprint.

Sustainable Raw Material Utilization

Pulp molding technology utilizes waste paper as its primary raw material, promoting recycling and waste reduction. This process not only diverts paper waste from landfills but also conserves natural resources by reducing the demand for virgin paper. The sustainable sourcing of raw materials makes pulp molding a key player in the circular economy, where resources are reused and recycled to minimize waste.

Lower Carbon Emissions

The production of pulp-molded tableware is associated with lower carbon emissions compared to plastic manufacturing. The energy-intensive processes of plastic production, such as petrochemical refining and polymer synthesis, release substantial amounts of greenhouse gases. Pulp molding, on the other hand, relies on renewable energy sources and efficient drying systems to minimize its carbon footprint, contributing to the fight against climate change.

Economic Advantages

Cost-Effective Production

Pulp molding machines offer cost-effective production by utilizing low-cost raw materials and efficient manufacturing processes. The abundance of waste paper as a feedstock ensures a stable and economical supply chain, reducing production costs. Additionally, the automated nature of modern pulp molding machines minimizes labor requirements, further enhancing cost-efficiency.

High-Volume Production Capability

Pulp molding machines are designed for high-volume production, making them ideal for meeting the growing demand for sustainable tableware. The ability to produce large quantities of products in a short period allows manufacturers to scale their operations and capture a significant share of the market. This scalability is essential for businesses looking to expand their product offerings and increase profitability.

Market Opportunities

The increasing consumer preference for sustainable products presents lucrative market opportunities for pulp-molded tableware. Businesses that adopt pulp molding technology can differentiate themselves by offering eco-friendly alternatives that align with consumer values. The versatility of paper tray making machine also enables manufacturers to produce customized products for specific markets, catering to diverse customer needs and preferences.

Technological Advantages

Advanced Molding Techniques

Modern pulp molding machines employ advanced techniques to ensure precision and consistency in product quality. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies enable the creation of intricate molds that produce high-quality tableware with superior aesthetic appeal and functionality. This precision ensures that pulp-molded products can compete with their plastic counterparts in terms of performance and appearance.

Automation and Process Control

Automation plays a critical role in enhancing the efficiency and reliability of pulp molding operations. Automated systems streamline the entire production process, from pulp preparation to product finishing, reducing human intervention and minimizing the risk of errors. Real-time process control and monitoring ensure that production parameters are optimized for maximum yield and quality.

Energy Efficiency

Energy efficiency is a key focus in the design of modern pulp molding machines. By incorporating energy-saving technologies, such as heat recovery systems and optimized drying processes, manufacturers can reduce energy consumption and lower operational costs. This energy efficiency not only contributes to environmental sustainability but also enhances the overall competitiveness of pulp molding operations.

Challenges and Considerations

Raw Material Quality

The quality of raw materials can significantly impact the performance and output of pulp molding machines. Impurities and contaminants in the waste paper can affect the strength and appearance of the final product. Manufacturers must implement rigorous quality control measures to ensure that the feedstock meets the required standards for pulp molding.

Technological Investment

While pulp molding machines offer numerous advantages, the initial investment in advanced machinery and technology can be substantial. Businesses must weigh the long-term benefits against the upfront costs to determine the feasibility of adopting pulp molding technology. Government incentives and subsidies for sustainable manufacturing can help offset these costs and encourage adoption.

Market Competition

As the demand for eco-friendly products grows, competition in the pulp-molded tableware market is intensifying. The pulp molding machine manufacturers must continuously innovate and improve their product offerings to stay ahead of the competition. Building strong relationships with distributors and retailers, as well as investing in branding and marketing efforts, can help businesses establish a competitive edge in the market.

Conclusion

Pulp molding machines offer a compelling solution for producing sustainable tableware that meets the demands of environmentally conscious consumers. By leveraging the environmental, economic, and technological advantages of pulp molding technology, businesses can enhance their competitiveness and contribute to a more sustainable future. As the world continues to prioritize sustainability, the adoption of pulp molding machines for tableware production is poised to play a pivotal role in the transition towards a circular economy and a greener planet.