Due to increasing production of rubber products, there is an increase in waste rubber. Generally, waste rubber is regarded as trash and disposed off through incineration or by burying it in landfills. However, technological improvements have made it possible to recycle waste rubber in a beneficial way. This is where the rubber recycling machinery comes into action.

The machine is also known as the waste rubber recycling machine. It crushes the whole rubber into tiny rubber granules/powder in sizes of 25 to 300 meshes. The powder or granules obtained from waste rubber could be reprocessed for making new products such as rubber damping cushion, soles, auto parts, artificial turf, rubber carpet, floor mat, rubber track, and other products.

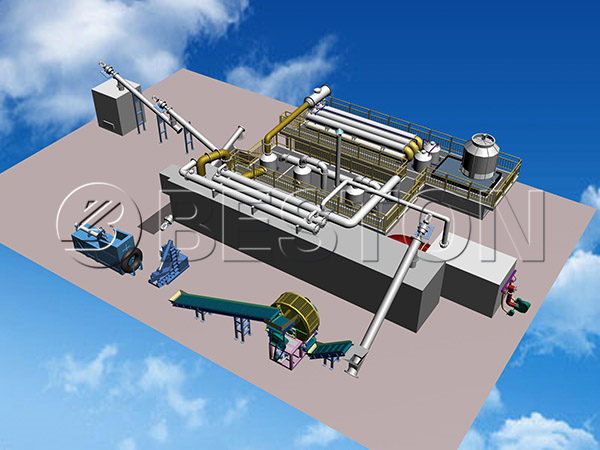

Rubber recycling process

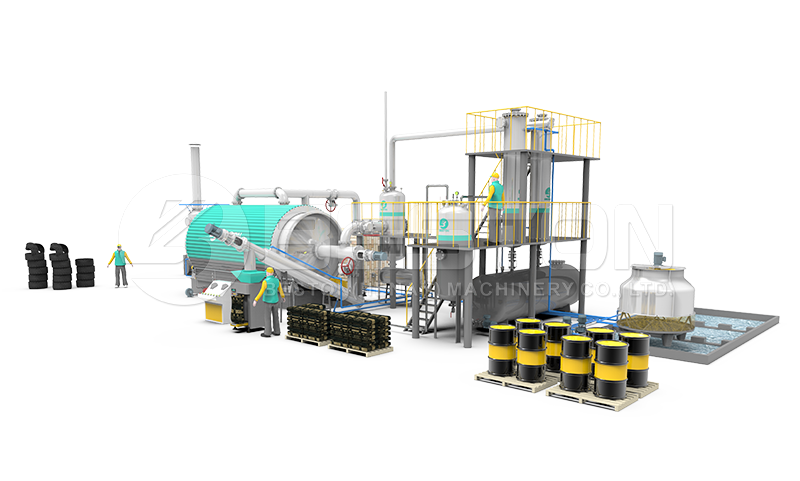

Modern rubber recycling equipment adopts an advanced recycling process to get better output. First of all, waste rubber is fed in the rubber pyrolysis machines through auto or manual feeding system depending on the types of machine you choose. However, many businesses choose the auto feeding system to save time and resources.

Wet (rubber) waste can’t be processed. For this reason, the waste is dried through the drying system. Once the material is dry, it’s passed through the heating furnace. Here the temperature is very high. At this high temperature, the waste gets recycled and the machine discharges oil gas and carbon black.

Uses of products generated by the rubber recycling plantAfter the waste materials are processed through the recycling equipment, you get carbon black, tyre oil, and combustible gas. All these end products are highly useful in many areas.

- Tyre oil

It’s sold as a fuel for glass, cement, ceramics, boiler, and other factories. Additionally, tyre oil is used in heavy oil generators. You can also refine tyre oil into diesel for tractors, trucks, and other vehicles.

- Combustible gas

It’s recycled for heating pyrolysis reactors. Additionally, combustible gas is used in many other industrial units as a fuel.

- Carbon black

Carbon black is reused for making tyres. It also has applications in the plastic industry.

Benefits of the rubber recycling machinery

The benefits stemming from the usage of this advanced machine are varied. Some of the important ones are detailed below.

- Rich and cheap raw materials

The rubber oil plant uses rich raw materials that are readily available. Some of the popular materials include waste rubber, waste tyres, oil sludge, and medical waste. All these materials are easily available at dirt cheap rates. However, the output resulting from the waste is pricey and highly beneficial.

- Enhanced safety

In any industry, safety is of utmost importance. You can’t compromise the safety of equipment and workers under any circumstances. To ensure safety, you ought to buy machines that come with better safety standards. It’s here the rubber recycling plant outsmarts others. The machine comes with some of the latest and upgraded safety measures in place. As a result, you can be sure of workers safety. Additionally, any instances of equipment damages are rooted out with better safety measures that give signals in times of need.

- Pollution-free

You may be happy to learn that the equipment doesn’t give out any harmful elements in the environment. The whole production process is free of smoke and noise. Instead, the machine plays a vital role in contributing towards a clean and green planet by doing away with waste tyres and rubber that can negatively affect the environment.

- Higher profits

Even in this highly competitive era, the rubber recycling plant yields better profits for certain reasons. Firstly, the raw materials used in the production process are cheap. However, the resulting output carries high value. Also, the machine is able to recycle large scale waste. Consequently, the production cost tends to be low with a high output. Low production cost and large scale output finally translates into better profits.

- Low investment

You may think that such a useful and profitable machine might be really pricey. However, that’s not the case. On the contrary, the machine comes at a reasonable cost. You can further ease your investment budget through installments.

Finishing words

Rubber recycling machinery tends to be one of the most recommended waste recycling plants in the market: kingtigergroup.com. Higher profits, low investment, pollution-free production, etc are a few of the perks of using this equipment. That’s why many smart businesses prefer this machine to create wealth from harmful waste.