Today 30% of garbage consists of plastic. As plastic doesn’t degrade fast it is very important to dispose of plastic waste properly. If not disposed of properly it can pollute the environment so any kind of plastic waste has become a problem for many individuals. Plastic not only pollutes the environment it also affects the metabolic disturbance in humans and marine animals. The best method to dispose of plastic material is to recycle it. The waste can include plastic bottles, rubber tires, oil sludge, and medical waste and so on. Pyrolysis plant is the key answer to reduce plastic waste.

What is Plastic pyrolysis?

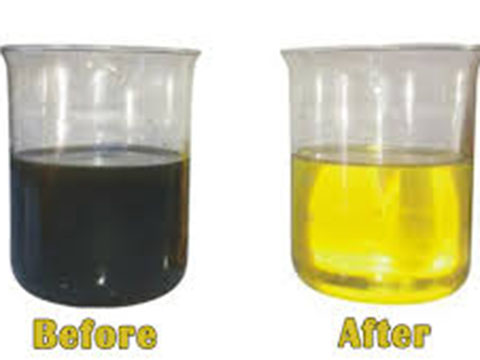

The pyrolysis technology aims to convert plastic waste into fuel-oil. It uses high temperature to turn plastic into carbon black. The end product received from pyrolysis technology gives useful resources which have wide range of application. The fuel oil derived from plastic pyrolysis can be used for the industrial purpose such as burning. Its refined version can be used as gasoline or diesel. Bricks can be created if you use carbon black with clay. These end products have good demand and can offer good price in the market. Especially fuel is helpful to reduce the energy crises. You can find detailed information about the waste plastics to fuel conversion process.

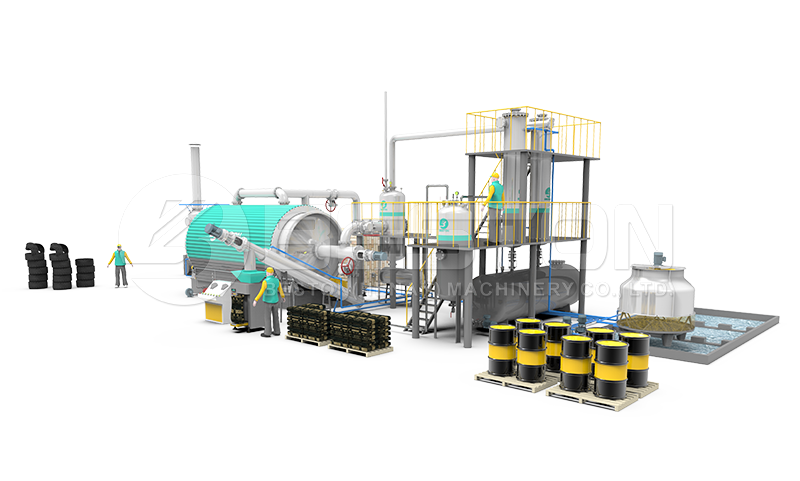

Features of Plastic Pyrolysis Machine

Besides the plastic to fuel machine for sale offer many beneficial features.

1. Safety

The biggest advantages of plastic pyrolysis machine for sale offers great safety. Vacuum system and hydro seal prevents the gas exhausted from going back to the reactors and condensers. This helps in avoiding accidents. Also, the machines are equipped with safety alarm systems and fire fighting systems. This can eliminate the danger in the process of production and offer safety to your workers.

2. Zero emission

The process generates a combustible gas which can be recycled as a fuel. This avoids contamination of gas and saves energy. The plastic pyrolysis machine also has the dust removal systems so the releasing gas is pollution free. This allows you to discharge the gas directly in the air.

3. Saves energy

The plastic to oil plants for sale uses the latest heating methods which not only saves the energy but also improves the reactor’s service life. The gas eliminated from the process can be recycled and used as fuel. It is an important factor you need to consider when you analyze the waste recycling plant cost.

4. High efficiency

This is one of the major advantages of plastic pyrolysis machine for sale. The machine are highly efficient and can provide better results in less time and power.