Modern egg tray manufacturing units have come a long way because of technology. In the past, producing these trays was a laborious effort on the part of those that had small chicken farms. Today, there are chicken farms that produce millions of eggs every year. These need to be shipped to locations that could be hundreds of miles away. To do this, they need to have the proper protection for the eggs. This is where the egg trays are used to store and transfer them to their destinations. Here are some of the latest innovations that can be found in most egg tray plant for sale.

What Has Changed In The Last Few Decades?

First of all, there are fully automated systems that are faster than ever before. Computers are able to control the flow of production, and also alert those that are monitoring the system to problems that need to be fixed. These alerts, combined with the faster production levels, allow these businesses to be much more efficient. That’s why many companies will acquire additional chicken farms to produce thousands of additional eggs every month. Another innovation is the use of conveyor belts once the egg trays have been fully dried. This saves time and allows more eggs to be placed in them in an orderly manner. Click here to know more about Bestpn Company.

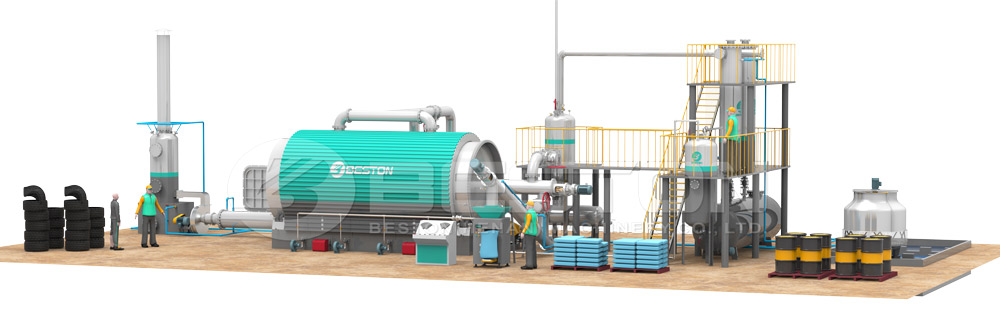

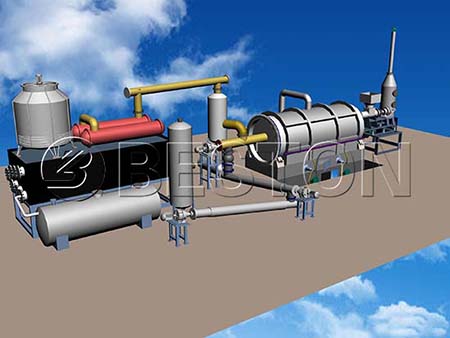

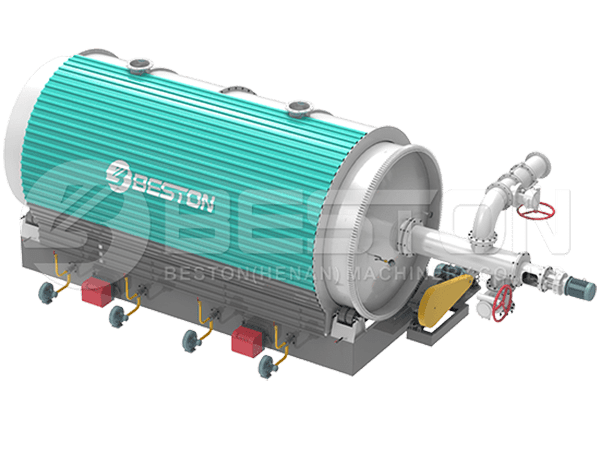

Your assessment of each of these machines is fairly easy to do if you know what to look for. First of all, there are components that must be part of the systems. You must have a hydrapulper that can process the raw materials into a pulp. You must have a wastewater pond, pulp pool, mixing pool, and a slurry pond. The pulp molding machinery is where this material will be utilized. Multiple trays of different sizes can be used to form egg cartons and egg trays. This will then be placed into a drying room which is equipped with modern burners that can be adjusted remotely. At the end of this will be a conveyor system that will take the finished products to a specific destination to be stacked. As you assess these different ones, you will notice that the fully automated egg tray machines will have the most robust conveyor systems.

Other Things To Consider Before You Make Your Purchase

The production capacity refers to the number of pieces that each of these units can produce. It is possible for some of the fastest ones that you produce as many as 5000 pieces per hour. The forming mold quantity refers to how many molds can be used in the drying room. This could be up to 60 at one time. You must also consider the electricity consumption, the labor force that will be needed, and the fuel consumption for each of these products. See the egg tray machine project report here.

The evaluation process is very easy once you have all of the parameters. These latest innovations in egg tray making machines have come a long way. You would not find the technology that is incorporated in them if you were to get one that’s even a decade old. That’s why it’s important to make an investment in your company if you are producing eggs on a daily basis. There are many businesses that offer the best machines in the industry, one of which will soon be yours if you are looking for a new one for your business.