Eggs tray and moulds are made from waste material like used paper, disposable glass, wooden chips and old newspaper.

Description of egg tray making machine:

Egg tray’s and egg carton machine for sale manufacturing industry is a leading industry. The use garbage in their factory to make new and use full items. Today world is facing extreme pollution problem. The garbage of house hold and factories are thrown any where. Water pollution, air pollution and earth pollution make miserable situation for human being. Now science and technology make a new terminology for cleaning world from garbage- Recycling process.

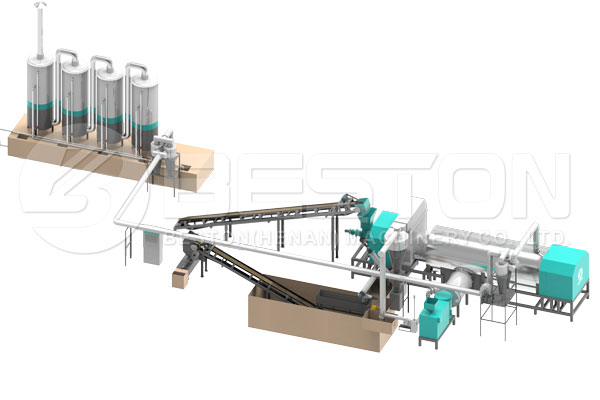

Recycling:

Recycling is the process of reusing the waste material into other product. Simply, the process of reshaping the waste material into useful item is known as recycling. Recycling industry make a worth position in the world. They introduce many machines and methodologies to reduce pollution. Chemical reactions, reshaping and reuse make a world to survive from its pollution.

Paper pulp:

Pulp is the raw form of making papers. Firstly, wood is converted into pulp. It is like a think paste of wood, water, wood fibres and chemicals. Then through certain machinery, the thick paste is proceed and make a paper. Paper pulp is also made from used vegetables, minerals, bark and straw etc. They are converted into a compressed form, removed all extra or unnecessary components and converted into pulp: https://www.bestongroup.com/pulp-molding-machine/products/.

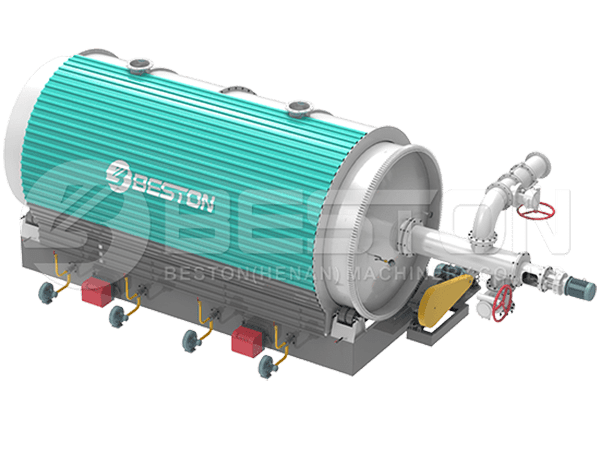

Technological components:

Pulp and paper making is the branch of engineering and science. This process emphasizes on the chemical reaction. Chemical known as sulphite acid and limestone, are combined to make a calcium bisulfide. They dissolve wood fibres and wood chips into chemical pulping. Onwards proper chemical and temperature control compounds make it a paper pulp. You can start the business from a small one: https://www.bestongroup.com/egg-tray-making-machine/manual/.

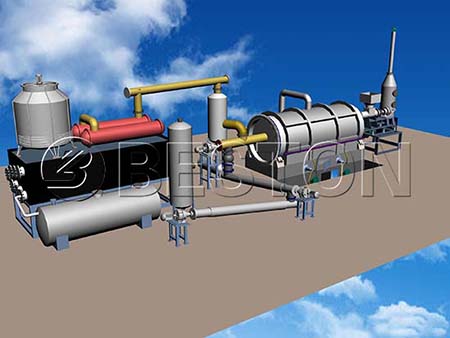

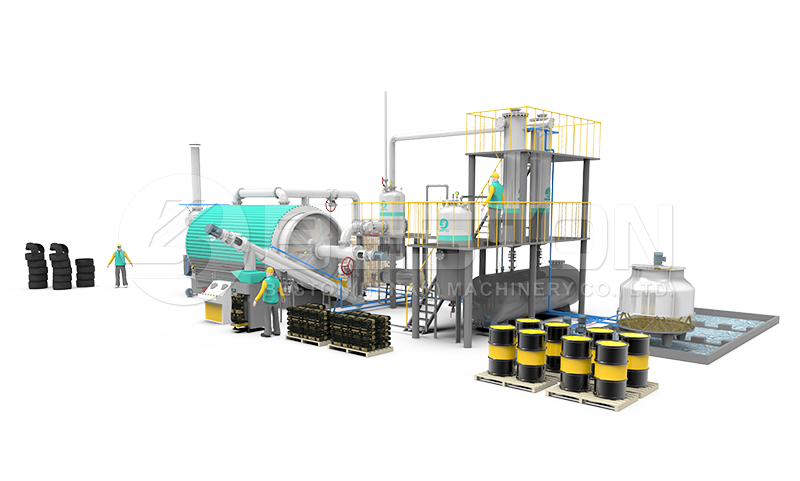

Working process:

When the wood chips and raw material is combined into liquid form, some dough maker component make a think dough. Steel less steel mould are fixed to machine and put the raw material in the moulds to make a specific shape tray.

Moulding tray:

Moulding are the holding case of eggs. Egg shell is so think that with a thingy force break it. To protect eggs from breaking or fracturing theeggs.

Benefits of eggs tray’s :

·Keep the egg into its natural status: Eggs are the rich source of protein. Egg yolk is more healthy as compare to egg white. When eggs are laid by hens, the yolk and egg white have possibility to mix in the shell. Moulding tray’s hold the eggs in it natural state.

·Protection fro breaking: Egg shell are so think and easy to break it. Egg tray give support to the eggs. They have their separate space to hold on.

·Easy to transport: farm house is a healthy business unite with high revenue profit. Although these farm house need proper equipment’s to supply their product in the market. (See egg tray making machine in Pakistan here.)

·Kept as bulk: Eggs’ tray allow the user to keep more eggs. These tray’s are available in many sizes as 12 eggs capacity or 24 eggs container.

·Proper shelter: from the form house to market and than to house, eggs need proper care. Egg tray and egg’s carton give a from strong support.

·Ideal for import and export: many countries exports eggs to the other countries. These egg tray’s allow them to keep their product more secure and collective.

·Keep them fresh: before putting into tray’s, eggs are properly checked as to confirm the freshness of eggs. Egg tray machine China was initially made by Taiwan’s company, later on made by chines company on low rate. This technology aware a common man to make new business. Recycling industray is now runs by government level as this industry has following benefits.

·Reuse waste material : Egg tray are made from waste material which is almost found every where. It help to clean the environment.

·Large Labour force required: This industry involved large number of labour as this is a long term process. Collecting garbage, selection useful material, suppliers and many more.

·Cheap products: As the raw material is cheap the product

will alternatively cheaper. The cost of making product is almost

free as the main material available-waste things, everywhere.

·New products : through this machine many new shapes and items are made easily. It encourages new experiments.

Drawbacks

·Health issue : during collection and recycling waste material, health issues arise. Many dieses and bacteria are found in garbage’s.

·Chemical uses: using more chemical also made health issue. More the chemical using in the production, more the health issues arise.

·Food serving items: now the paper egg tray making machine in india allows to make new items as plate, lunch box and many more. Which directly effect human health.

·Eggs life: when eggs tray and carton are once packed, air circulation stop. It affect eggs quality.

Conclusion:

Recycling of waste material is aleading. It encourage small scale industrial to expend her/his business.