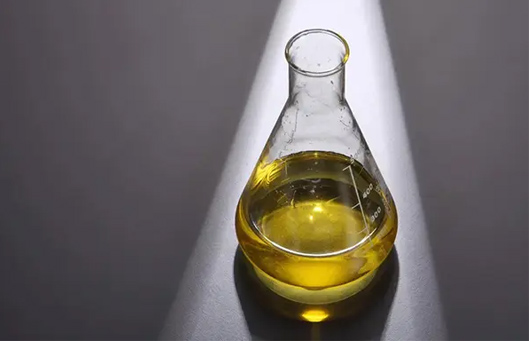

In recent years, pyrolysis has emerged as an innovative method to convert waste materials into valuable resources. Among the many products derived from this process, pyrolysis oil stands out due to its high energy content and versatility. However, not all materials produce the same amount of oil when subjected to pyrolysis. Understanding which materials yield the most oil is essential for industries and entrepreneurs looking to maximize efficiency and profitability.

Factors Affecting Oil Yield in Pyrolysis

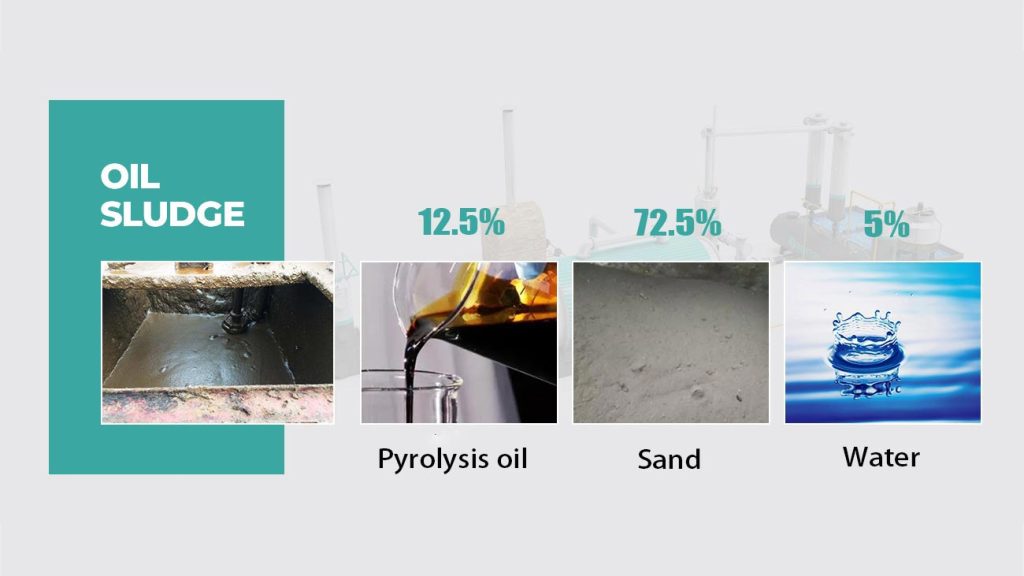

The amount of oil obtained from pyrolysis is influenced by several factors. Temperature, heating rate, residence time, and the type of feedstock all play crucial roles. Generally, materials with high carbon and hydrogen content tend to produce more liquid products. Moisture content is another important factor; wet materials usually reduce the overall yield since water absorbs heat and may form unwanted byproducts.

Comparing Different Pyrolysis Feedstocks

Among various feedstocks, plastics, tires, and biomass are commonly studied. Plastics, especially those rich in hydrocarbons such as polyethylene and polypropylene, are known to generate high oil yields. Similarly, waste tires, which contain both natural and synthetic rubber, also produce significant amounts of oil, though slightly less than some plastic types. Biomass materials like wood, agricultural residues, and food waste generally yield lower amounts of oil, with a higher fraction of char and gas.

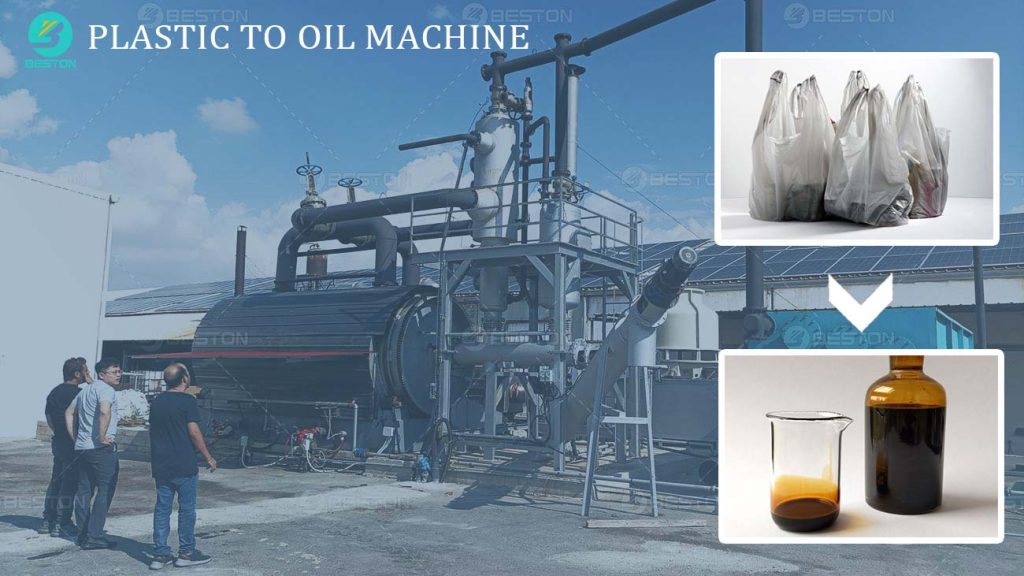

Plastic Waste and Oil Production

Plastic waste is often highlighted for its superior pyrolysis performance. Plastic pyrolysis equipment is designed specifically to handle various plastic types and maximize oil recovery. The hydrocarbons in plastics break down efficiently under heat, producing a high volume of liquid fuel. This makes plastic an attractive feedstock for commercial pyrolysis operations, particularly in areas struggling with plastic pollution.

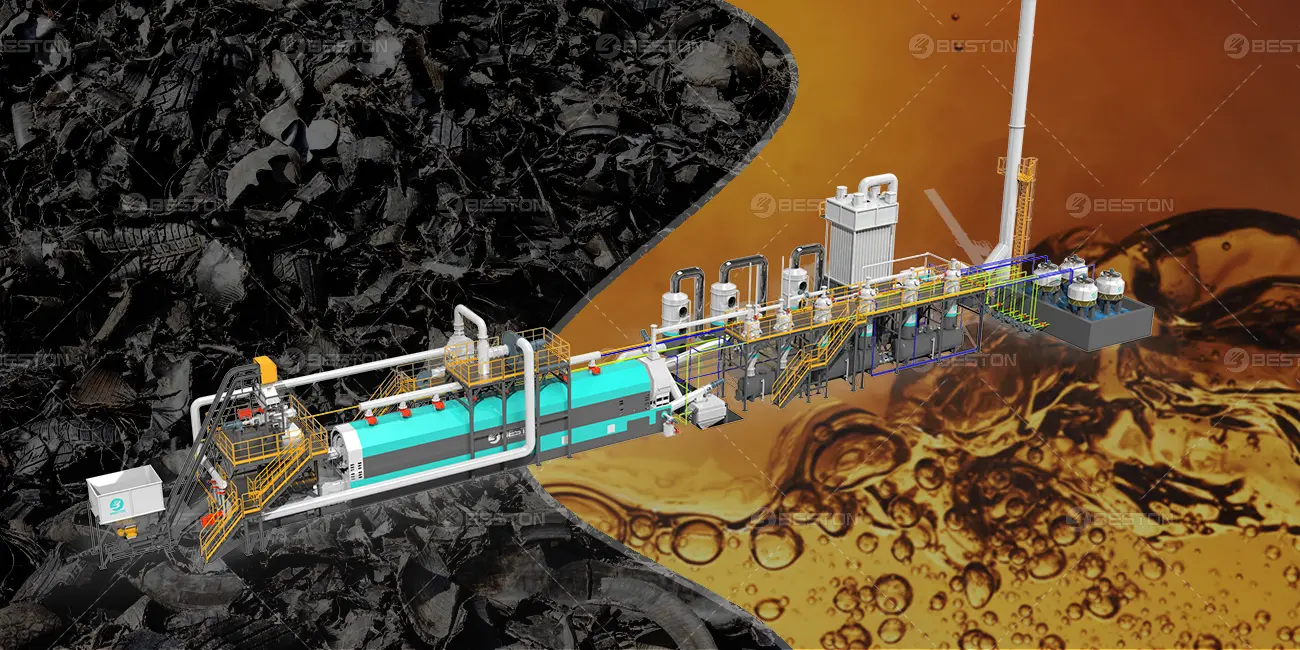

Tyres as a Valuable Feedstock

Waste tires are another material that generates a considerable oil output. Specialized tyre pyrolysis equipment can process shredded tires, recovering oil, carbon black, and steel. While the oil yield from tires is slightly lower than that from some plastics, it remains economically viable due to the abundance of scrap tires and the market value of the byproducts. Additionally, tire oil has properties suitable for industrial fuel applications.

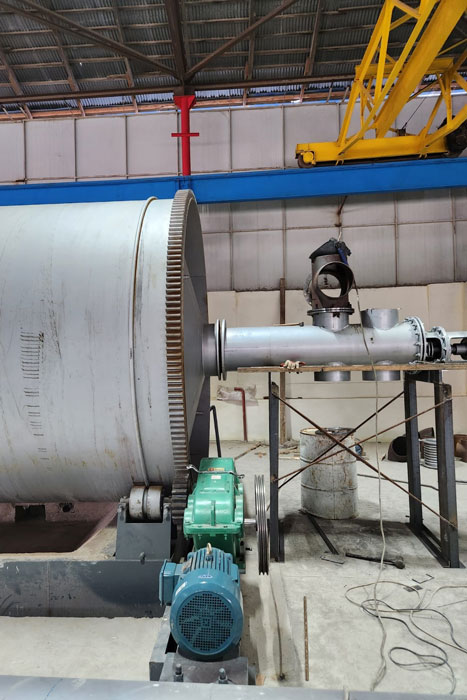

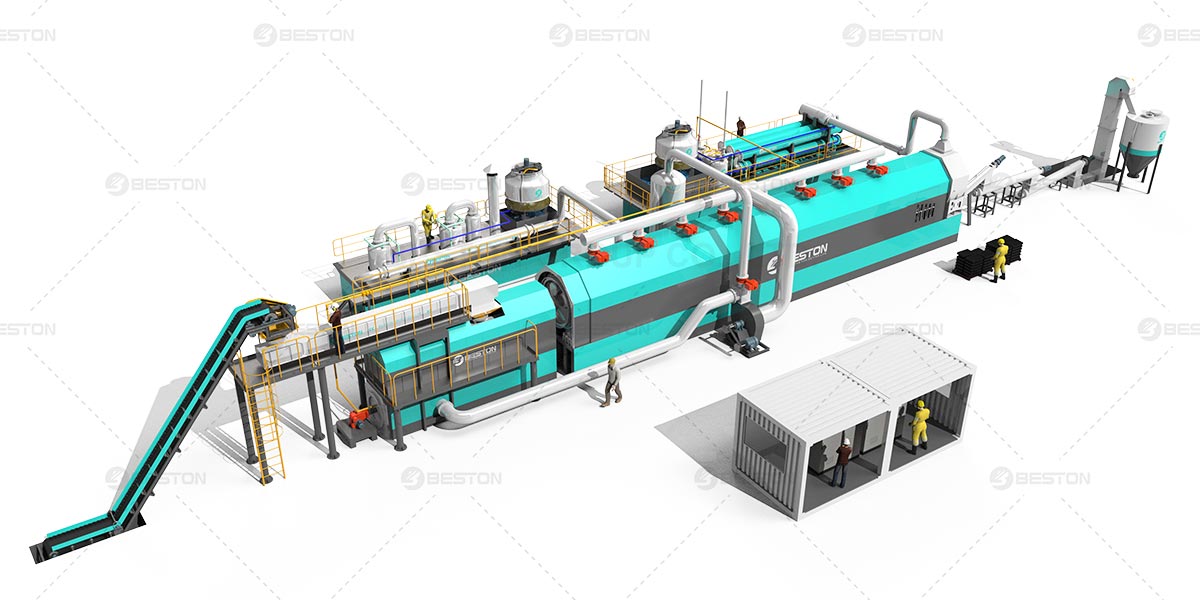

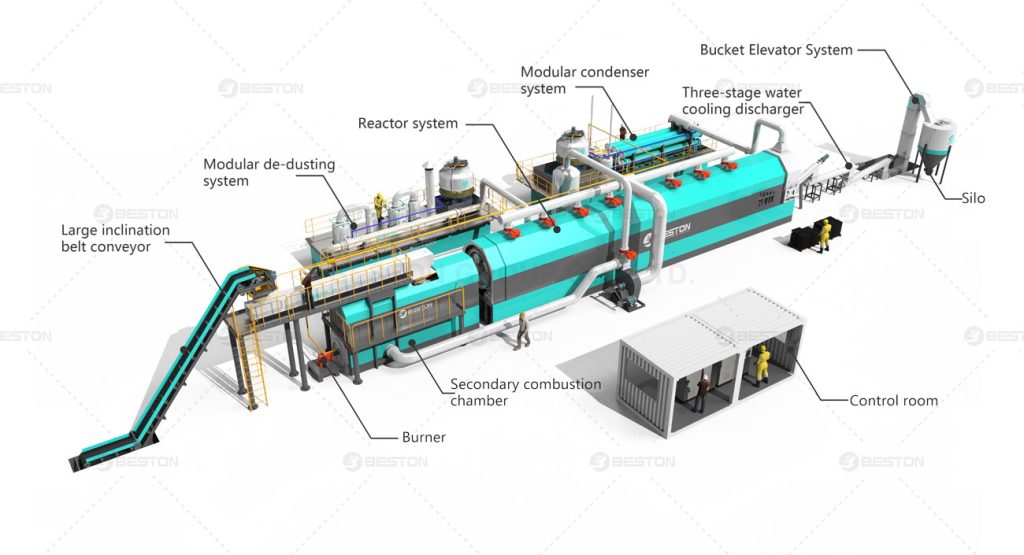

Optimizing Pyrolysis Processes

Regardless of the feedstock, optimizing pyrolysis parameters can significantly enhance oil yield. Using advanced pyrolysis equipment with precise temperature control, effective condensers, and efficient gas recycling can improve conversion efficiency. Continuous feeding systems, proper insulation, and controlled heating rates also contribute to maximizing liquid product recovery while minimizing unwanted residues.

Environmental and Economic Considerations

High oil-yielding materials not only offer economic benefits but also environmental advantages. Converting plastics and tires into liquid fuel reduces landfill pressure and limits pollution. Selecting feedstocks that yield more oil can make pyrolysis plants more sustainable, balancing energy recovery with waste management. Operators must also consider the logistics of material collection and processing costs to ensure long-term profitability.

In conclusion, the choice of pyrolysis feedstock is crucial in determining the oil yield. Materials rich in hydrocarbons, such as plastics and tires, generally produce the highest amounts of oil. Properly designed and operated equipment can further enhance recovery, making pyrolysis a viable solution for both waste management and energy production. More in Beston Group.