Tyre pyrolysis is the process of breaking down tyre polymer chains into smaller molecules by heating them up in a controlled environment. This can be done through a variety of methods, but the most common is thermal decomposition – heating tyres until the chemical bonds break and release gas. The gas can then be captured and used as fuel or other products. Pyrolysis plants are becoming more popular as a way to dispose of old tyres, so here’s what you need to know about them.

Understanding the Pyrolysis Process

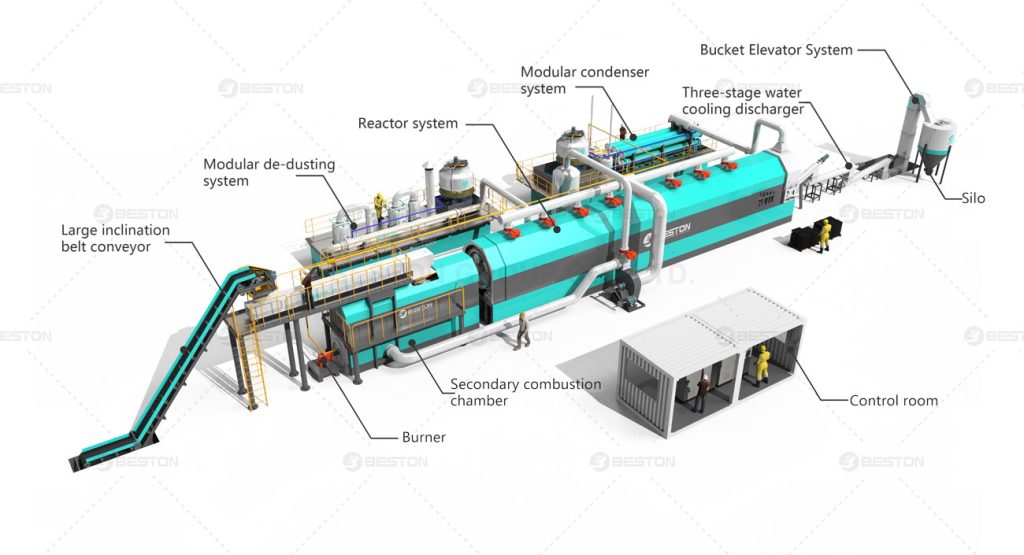

Pyrolysis involves the use of extreme temperatures for the thermal decomposition of organic material. In a tyre pyrolysis plant, this process is used to break down waste tyres into useful products, such as fuel oil, carbon black, and steel wire. The main benefit of this process is that it helps reduce the volume of waste tyres, making them easier to recycle or dispose of.

In addition, the products of pyrolysis can be used in a variety of applications, such as fuel for furnaces or boilers. If you are considering setting up a tyre pyrolysis plant, there are a few things you need to know. Firstly, you will need to obtain a license from your local authority. Secondly, you will need to purchase the necessary equipment, such as an incinerator or autoclave. Finally, you will need to find a suitable location for your plant. With careful planning and research, setting up a continuous pyrolysis plant can be a successful and environmentally-friendly way to deal with waste tyres.

The end products of tyre pyrolysis are gas, liquid and solid.

The gas produced by a tyre pyrolysis plant can be used as fuel. It can be combusted to generate heat or electricity, or it can be used in industrial processes such as steel production.

The liquid product of tyre pyrolysis is known as pyrolytic oil. This can be used as a fuel in its own right, or it can be refined and used as a feedstock for the production of plastics and other chemicals. Get waste tyre pyrolysis plant cost here.

The solid product of tyre pyrolysis is known as carbon black. This can be used as a reinforcing agent in rubber products, or it can be mixed with asphalt to create durable pavements.

Evidently, a tyre pyrolysis plant provides an environmentally friendly solution for disposing of waste tyres. The end products of the process have a range of uses, making the tyre pyrolysis plant a versatile and valuable piece of equipment.

Consult With an Expert Before Making Your Purchase

Pyrolysis plants offer a sustainable solution for recycling waste tyres. In addition to recycling waste tyres, pyrolysis plants can also be used to recycle other types of waste, such as plastics and electronic waste. However, it is important to consult with an expert before making any decisions about purchasing a tyre to oil plant. There are many factors to consider, such as the type of waste to be recycled and the desired end products. With the help of an expert, you can find the right pyrolysis plant for your needs and ensure that it is operated safely and efficiently.