Sometimes you may need a crane to transport heavy cargo or for manufacturing purposes. Overhead cranes and underhung bridge cranes both have practical uses, but there is a time and place for each. This article will compare the differences between top running overhead crane and underhung bridge crane.

One primary difference between overhead cranes and underhung bridge cranes is that the underhung bridge cranes are far more versatile. Underhung bridge cranes usually carry lighter objects. Because of this the underhung crane system is also much lighter.

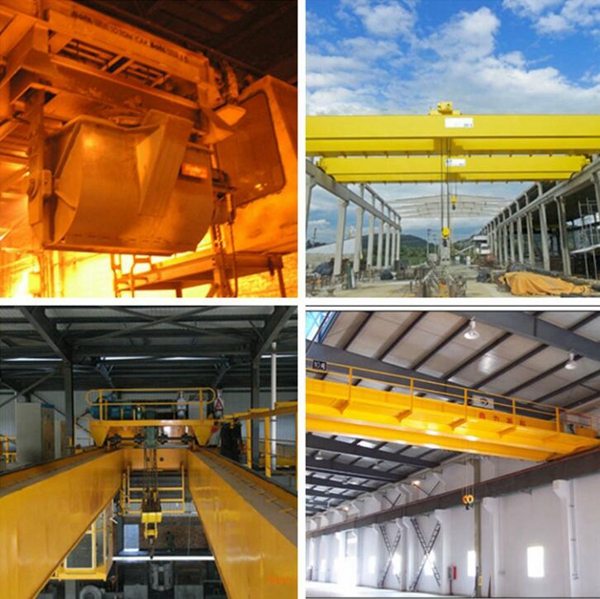

Overhead cranes are used to carry and transport extremely bulky and heavy objects. If your business needs to move or produce heavy cargo, then it’s a necessity to have an overhead crane system in your building, warehouse, or industrial park.

Another major difference is the positioning of the end trucks. For underhung crane systems the end trucks tend to operate on the lower part of runway beams. The end trucks for overhead cranes require rails for support. These rails link up to the top of the crane runway.

Underhung bridge crane systems tend to be cheaper than their overhead counterparts. This is because underhung systems are more flexible, can utilize multiple runways, and are much lighter. Underhung crane systems also have the ability to line up parallel with other underhung crane systems. This allows for more cranes to be running simultaneously, which leads to optimal production.

Top running overhead crane systems are perfect for the transport or production of very heavy loads. If your business needs to consistently transport cargo heavier than twenty tons or more, then an overhead crane system is a necessity. In order to have a top running overhead crane system, the building support steel needs a bracket attached. For extremely heavy loads the use of support columns will be needed.

Another difference between the two support systems is that top running overhead systems are perfect for businesses that require more headroom. This is because they run along the overhead runway. The end result is more headroom, which is perfect for low headroom facilities, or facilities with extremely high headroom.

Underhung Bridge Cranes work perfectly along a fixed path. An interlock mechanism allows for underhung systems to be interconnected. Underhung crane systems also allow for the use of track switches. Track switches allow for multiple locations, and the transfer of cargo from incoming tracks to outgoing tracks.

To lower the need for load re-handling, it is wise to invest in multiple interconnected overhead crane systems. Instead of purchasing one expensive system, using an interlock to purchase two overhead connected systems will cost less money. Using interlocks are the key to running a fluid overhead system capable of running smoothly through the whole facility.

The type of system you need depends completely on many factors. For smaller cargo or production facilities, underhung bridge cranes are a smart investment. Underhung bridge systems are less expensive overall and offer much versatility. Top running overhead cranes are perfect for transporting heavy cargo or items over twenty tons. For more types of overhead cranes, you can visit http://ellsenoverheadcrane.com/.