Investing in a charcoal making machine can be one of the smartest business decisions ever. You can use biomass waste other people want to get rid of to make something useful and to sell it for a nice profit. This article shows you how to shop around for a palm kernel shell charcoal making machine and how to ensure you pick a reliable supplier.

The first thing to know is that you won’t have to travel overseas to meet suppliers face to face. Thanks to modern technology, you can search for charcoal making equipment and order it online, and have it delivered and installed on your production site without having to leave your office. There are virtual marketplaces and industrial directories where you can find the full range of charcoal making machines and accessories, with cost and performance details. Reaching out to the vendors of these machines is as easy as sending them a message or using the chat features on those websites to ask them everything you want to know about their products.

As the charcoal making machine price may vary between USD 2,000 and USD 90,000, you’ll need to start by deciding upon a reasonable budget to spend on your equipment. Also, you’ll have to estimate your production needs in terms of raw material, functions, effective volume, energy-saving features, purification system, and additional services.

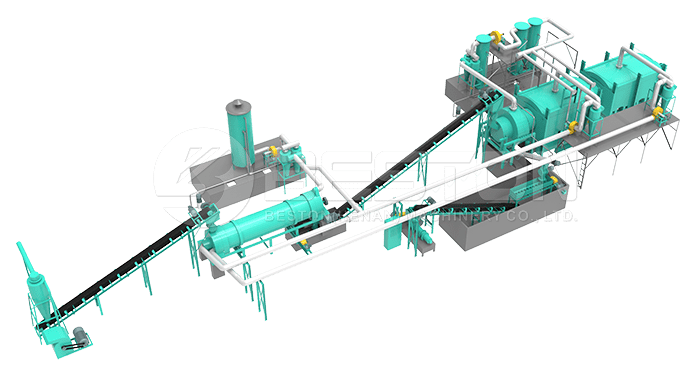

There are machines with shorter carbonization and cooling times, and machines with longer production cycles. The general rule is that smaller capacity machines have shorter carbonization times and also shorter cooling times. You can expect such a machine to need 4-6 hours for turning the palm kernel shells into charcoal and about 10 hours to cool the charcoal. These machines have a capacity of 300kg. There are also machines with a capacity of 500kg, requiring 6-8 hours carbonization time and 14 hours cooling time. If you need a larger capacity, you can choose a 1000kg machine, with 10-12 hours carbonization time and 20 hours cooling time. The advantage of using higher capacity machines is that you can make bigger batches of charcoal, thus being able to deliver your customers a high-quality and consistent end product without having to process multiple batches of raw material. Beston Machinery offers continuous biochar production equipment for sale, which can feed and discharge charcoal at the same time. Here is the website for you: https://bestonasia.com/biochar-production-equipment/.

Each element of the machine has its own importance in the biochar production process. The end gas burner, the inside furnace, the outside furnace, the heating chamber, and even the cover can have a direct influence on the quality of the charcoal. This is why you need to perform an exhaustive analysis of all technical parameters of the palm kernel shell carbonizing stoves before making your final purchasing decision.

Also, check the credentials and the work experience of the manufacturers on your shortlist, to ensure you won’t end up with a poor quality machine or with unreliable maintenance and repair services. If needed, ask these sellers to share a few client references with you, so that you can check on them before placing your order. After you receive your quotes from all companies on your shortlist, compare them, and pick the best one. If you want more details, please check the link here: https://bestonasia.com/.