In a world where sustainable agriculture is gaining paramount importance, innovative solutions are emerging to address the need for soil enrichment, carbon sequestration, and waste utilization. One such groundbreaking innovation is the mobile biochar machine, a versatile and eco-friendly technology that is transforming the agricultural landscape. In this comprehensive 1500-word post, we will explore the concept of mobile biochar machine, their functionality, environmental benefits, applications, and their role in shaping a more sustainable future for agriculture.

The Soil Enrichment Challenge

The foundation of productive agriculture lies in fertile soil. However, continuous farming practices have led to soil degradation. This chapter introduces the critical issue of declining soil fertility and highlights the role of biochar in soil enrichment.

Biochar Basics

Before delving into biochar equipment, it’s essential to understand the fundamentals of biochar. This chapter explains what biochar is, how it’s made, and why it’s an attractive solution for soil improvement.

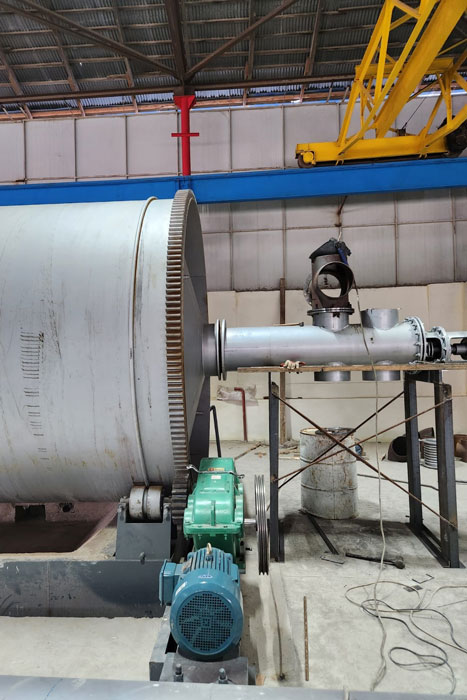

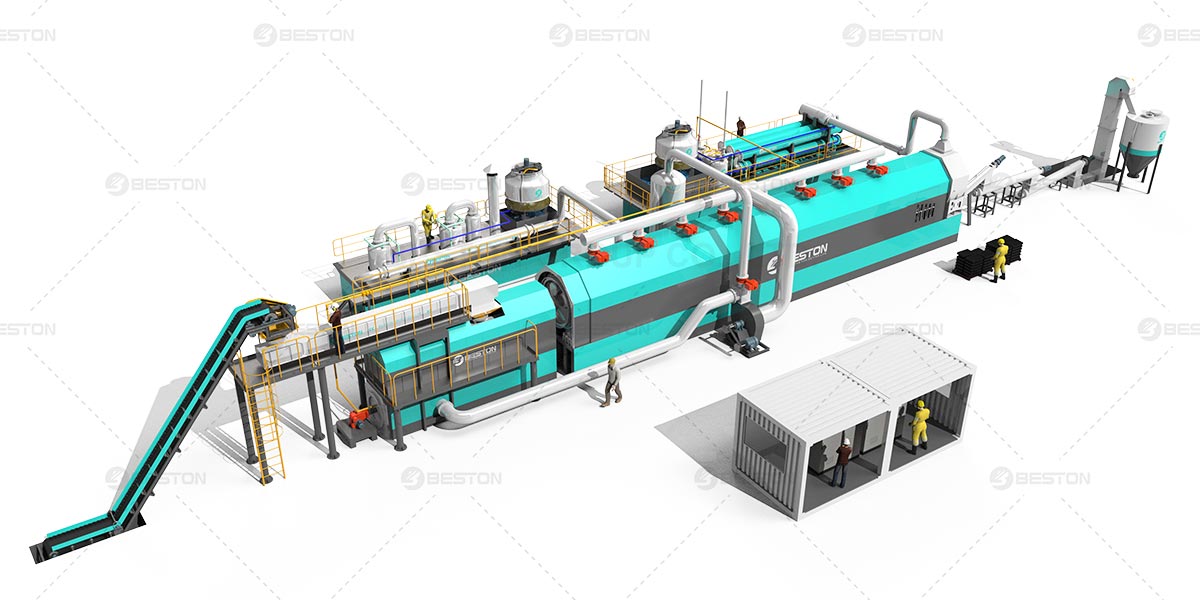

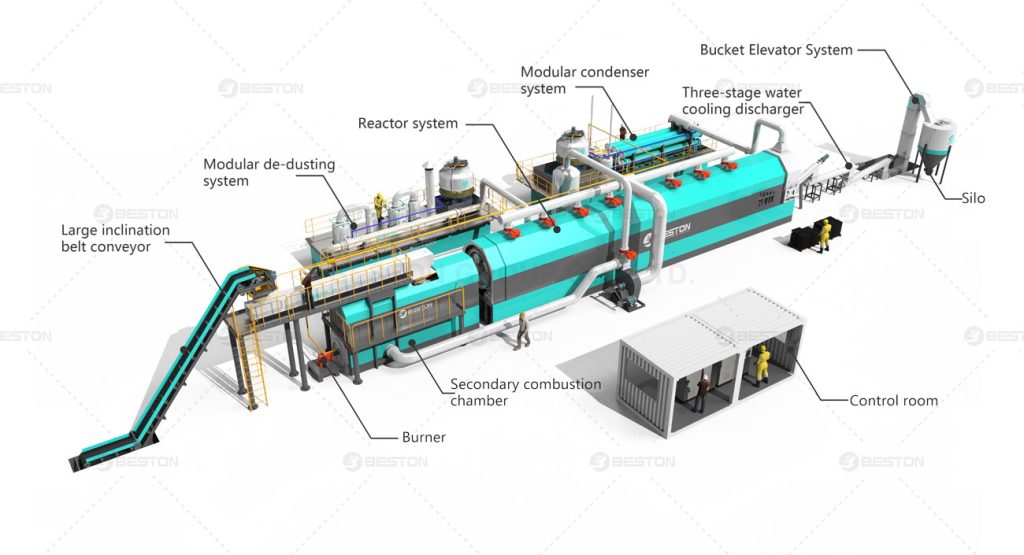

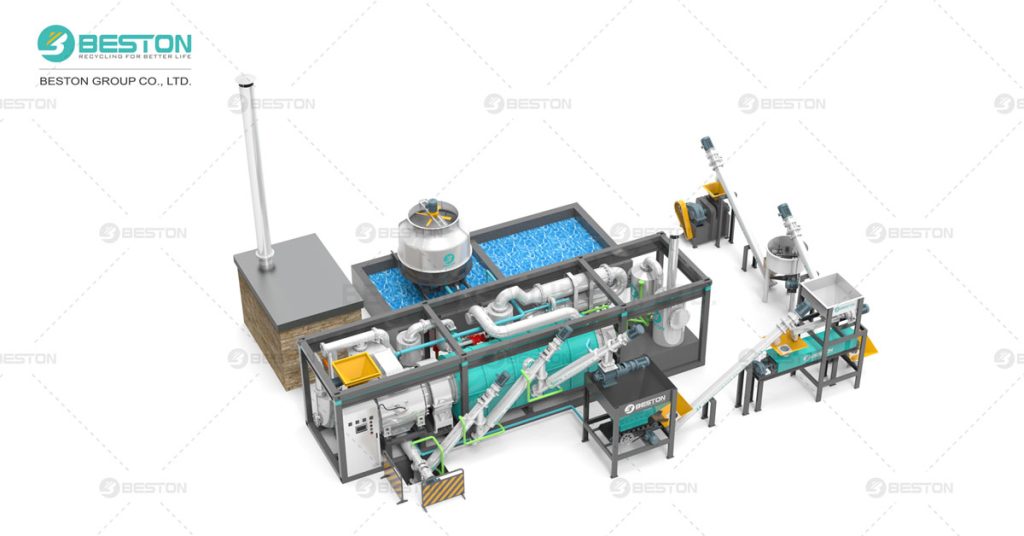

Enter the Mobile Biochar Machine

Mobile biochar machines bring the benefits of biochar production directly to the field. This chapter provides an in-depth look at the design and functionality of these portable units, including their size, mobility, and the processes involved in converting biomass into biochar.

Biochar Production On-Site

One of the key advantages of mobile biochar machines is the ability to produce biochar on-site. This chapter explores the advantages of this decentralized approach, including reduced transportation costs and increased efficiency.

Environmental Benefits

Mobile biochar machines are celebrated for their environmental benefits. This chapter delves into these advantages, including carbon sequestration, reduced greenhouse gas emissions, and improved waste utilization.

Applications in Agriculture

The primary purpose of mobile biochar machines is to enhance agricultural practices. This chapter highlights various applications of biochar in agriculture, including improved crop yields, nutrient retention, and water management. Contact a biochar machine manufacturer to learn about the solution.

A Tool for Climate Change Mitigation

Given the urgency of climate change, this chapter discusses how mobile biochar machines contribute to mitigating its effects by sequestering carbon and reducing the carbon footprint of agriculture.

Challenges and Solutions

No technology is without its challenges. This chapter addresses common issues associated with mobile biochar machines, such as feedstock availability and scalability, and explores potential solutions.

Success Stories

Real-world examples demonstrate the effectiveness of mobile biochar machines. This chapter showcases success stories from farmers and organizations that have incorporated this technology into their agricultural practices.

Future Prospects

As the agriculture industry continues to evolve, so does the potential of mobile biochar machines. This chapter explores future trends, including technological advancements and potential policy support.

Conclusion: Cultivating Sustainable Agriculture

In conclusion, mobile biochar machines represent a significant leap toward sustainable agriculture. If you wanna watch more videos, view https://www.youtube.com/@bestongroup_. These portable units empower farmers to enrich their soils, reduce waste, and combat climate change, all while increasing crop yields and profitability. As the world faces the challenges of a growing population and changing climate, mobile biochar machines offer a beacon of hope for a more sustainable and food-secure future.