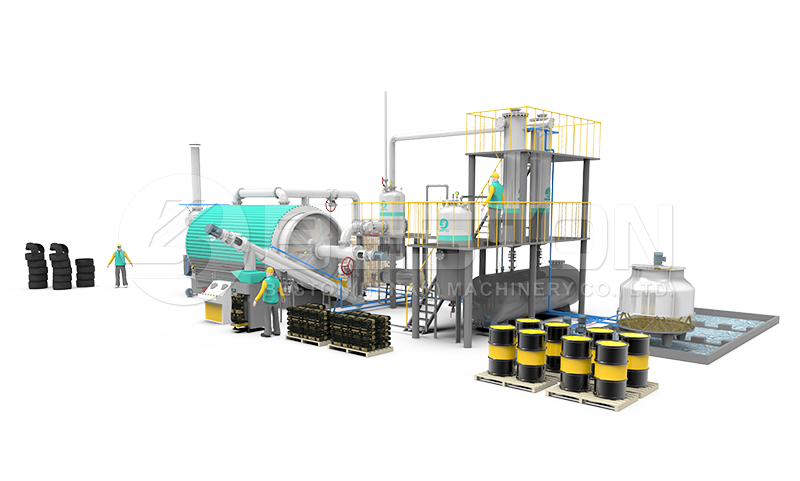

The pyrolysis equipment provides you with an affordable way to remove waste tires from the landfill. This machine is useful when you have a recycling business and you want to process tons of tires. The tires are heated up and turned into diesel or oil that can be processed into gasoline. This machine is a great investment in your business and it helps you make a lot of money fast.

It is important that you choose a machine that fits your budget which means that you need to look at the cost of the machine. The cost is going to depend on the size of the machine and how many tons of oil it will produce. The cost really varies and you should also make sure that you invest in the best machine that you can. Try to invest in the best machine that you can.

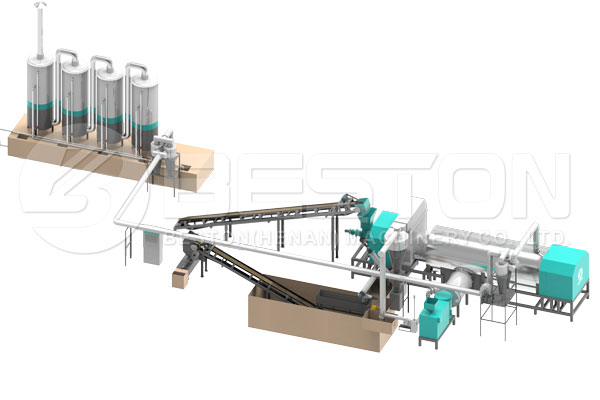

You need to have a budget when you are looking for the machine so you end up choosing exactly what you want. It helps to work with the manufacturer because they can help you choose the plant that is going to be the right size for your needs. Looking for one of these machines can be a challenge so make sure that you take the time to look for what you need. More models of tyre pyrolysis machine can be found: https://bestonasia.com/waste-tyre-pyrolysis-plant/.

When you are looking for a tyre pyrolysis machine you need to consider where it is going to go and how much oil you can produce with it. It helps to read all about the different models so you know which one to choose. The more you know about this machine the easier it is going to be to choose the right machine.

There are so many options with this machine and you need to take your time to learn all about the different models. Make sure that you work with the manufacturer and they will help you take care of your needs. Always buy the largest machine that you can afford because it will help you save money because you can produce more oil. Of course, you need to consider the tyre pyrolysis plant cost into consideration.

The larger machines have a larger output and this is good for your bottom line. You want to try to produce all of the oil that you can so you can make all of the oil that you need. The oil is easy to sell and you can quickly produce tons of oil with this machine. The machine heats the tires to a very high temperature and extracts the oil. The oil is high-quality and it can be processed into gasoline.

This machine is the perfect choice when you want to increase productivity with your business. You can make a lot of money fast with this machine and it helps you protect the environment by removing the waste tires from the landfills. Millions of tons of waste tires are produced each year and they don’t need to end up in the landfills when you invest in the tire to oil machine. The machine is a great investment in your business.