With the modernization of society, rubber is seeing greater use for transport and other uses. This has led to black contamination as landfills are increasingly having to bear the load of waste tyres. However, technology has come to the rescue and allowed plants to be set up that can convert tyres to oil and greatly reduce the environmental damage that tyres can cause when sent to landfills.

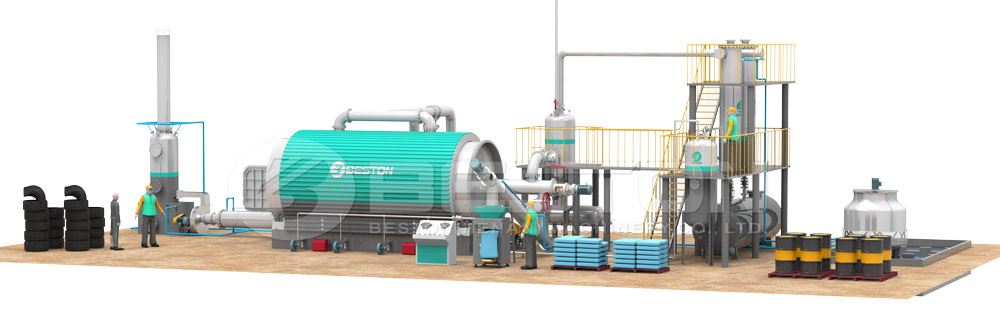

Setting up a waste tyre to oil plant that uses pyrolysis to make the conversion can bring many advantages. The main raw material for these plants is waste tyres, though the same plants can also use plastic, whose safe disposal has always been a major environmental concern. Both these raw materials are relatively cheap to obtain, while the output from these plants can be fuel oil, steel, gas, and carbon black. To set up these plants does not require a very high investment, and because of the high availability of raw materials, costs can be recouped within a very short time. The waste tyres can be recycled completely and there are no end products that may need further disposal.

The products that are the result of the pyrolysis of waste tyres, fuel oil, gas, and carbon black have a great demand in the market. The process does not need any catalysts or other intermediaries to be added, and every ton of tyres helps to preserve 10 tons of the major greenhouse gas, CO2. The entire process of pyrolysis does not add to pollution and is thus a very environment-friendly recycling method. Click here to know more: https://bestonpyrolysisplant.com/.

The oil that is produced by the tyre to oil plants can be sold directly to industries that use such heavy oil. Power generating plants are big users of this oil. The oil can also be further distilled and converted into gasoline or diesel. The carbon black that is a byproduct of the pyrolysis is used in many industries and can also be converted to coal or other refractory items. Find more information on https://www.plurk.com/BestonMachinery.