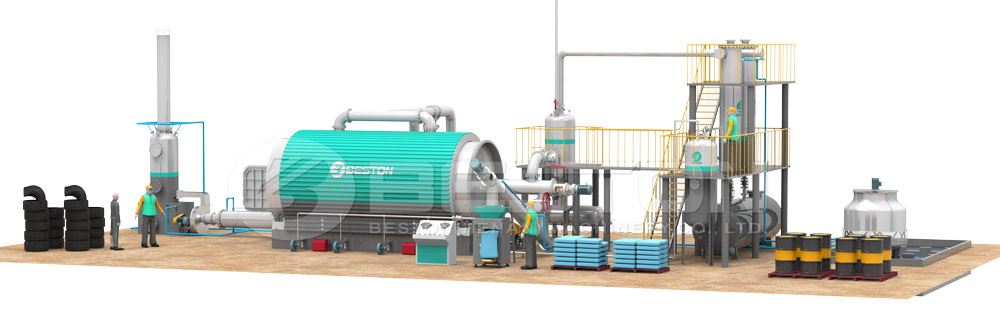

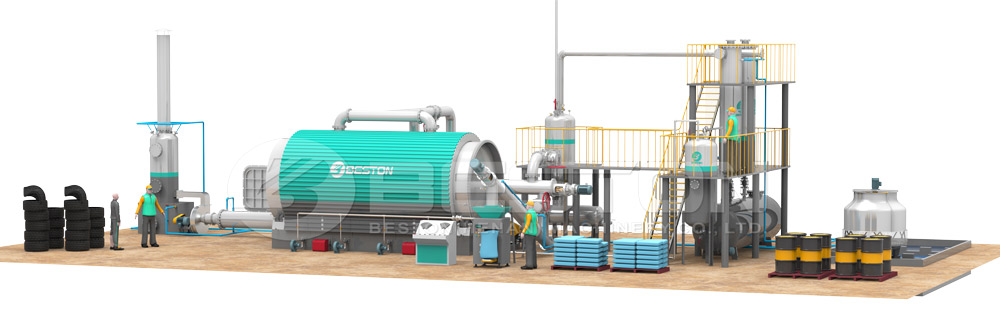

There is a difference between a pyrolysis plant that is fully automated and continuous and one that does require additional help from workers. Many of these plants are not capable of functioning longer than 12 hours without having to be cleaned out, reset, so they can be used once more. For those that are continuous, this process is possible because of the way they are designed. If you are processing rubber tyres on a daily basis, you want to go as fast as possible. You could be responsible for clearing out an area where there are many rubber tyres, sometimes totaling in the millions, at specific locations. To get a continuous tyre pyrolysis plant price that is affordable for you, follow the simple recommendations.

Why You Need One That Is Continuous

Although the prices on tyre pyrolysis plants can be expensive, you do want to go with one that is completely automated. It also needs to be continuous, producing the charcoal and other components on an ongoing basis. This is what’s going to keep your production levels high. Additionally, you should have a constant supply of the chipped up tyres ready to process so that you can keep producing material. Once you have the process streamlined, it will be very easy to keep up with, all of the different businesses that provide you with rubber tyres that need to be processed. Click here to know more: https://bestonpyrolysisplant.com/.

The term continuous is a bit of a misnomer. There will always be times when you will have to stop the plant in order to clean it, do repairs, or just simple maintenance. Additionally, you will also need to empty the reactors that will produce the material. By doing so, you can keep a constant flow of the material. In some cases, you may not realize how much material you can go through until you have gone through the first week. By then, you will have automated the entire process, using every aspect of the machines, that will help you maintain a continuous production of burnable products.

How To Get The Best Prices

To get the best rates on a continuous tire pyrolysis machine price, you must do some research, contacting as many businesses as possible. Some of them are going to have thousands of happy clients that of use their different pyrolysis machines over the years. Businesses that are more widespread, perhaps having customers in different areas of the world, are likely going to give you thousands of reviews. However, you may be looking for someone that has an above average machine that is continuous and also affordable.

Getting estimates on continuous tyre pyrolysis plant prices is the first step to finding one that is affordable for you. By the end of the week, you should have several estimates back from these well-known businesses that are selling these worldwide. Once it is set up in fully functional, your ability to produce as much charcoal and burnable fuel as you need will be maximized as you will have an exact system to follow. Always get ones that are capable of continuous production so as to maximize your profits when producing these materials. More information on Pinterest: https://www.pinterest.com/bestonchina/pyrolysis-plant-for-sale/.