In the relentless pursuit of sustainable solutions, the alchemy of pyrolysis stands as a beacon of innovation. This arcane process, shrouded in scientific intricacies, holds the key to unlocking the latent energy in diverse raw materials. Today, we embark on a journey into the world of pyrolysis, exploring its transformative prowess on four distinct raw materials: plastics, tires, oil sludge, and rubber.

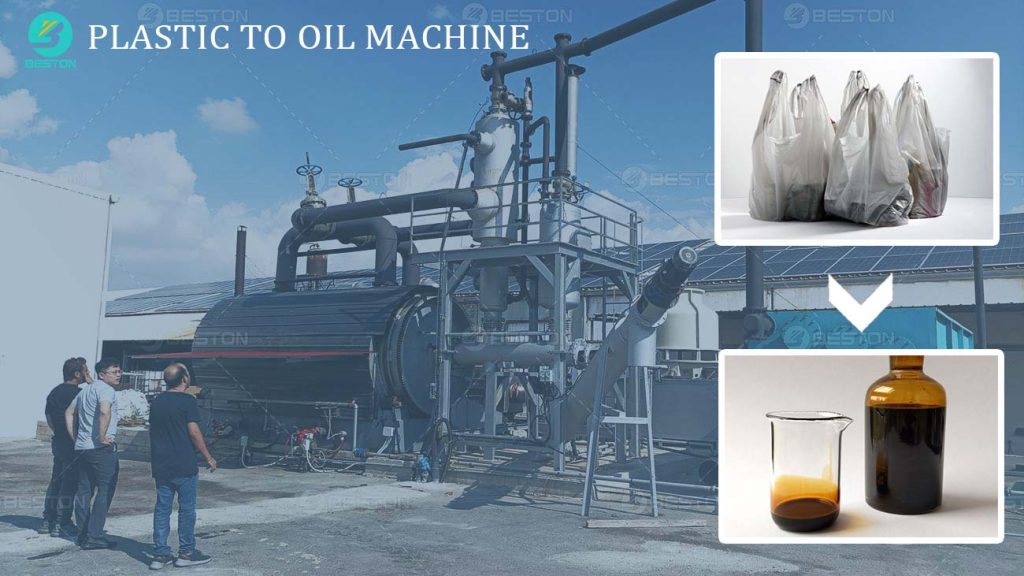

Plastic Pyrolysis Machine: Reshaping the Fate of Polymers

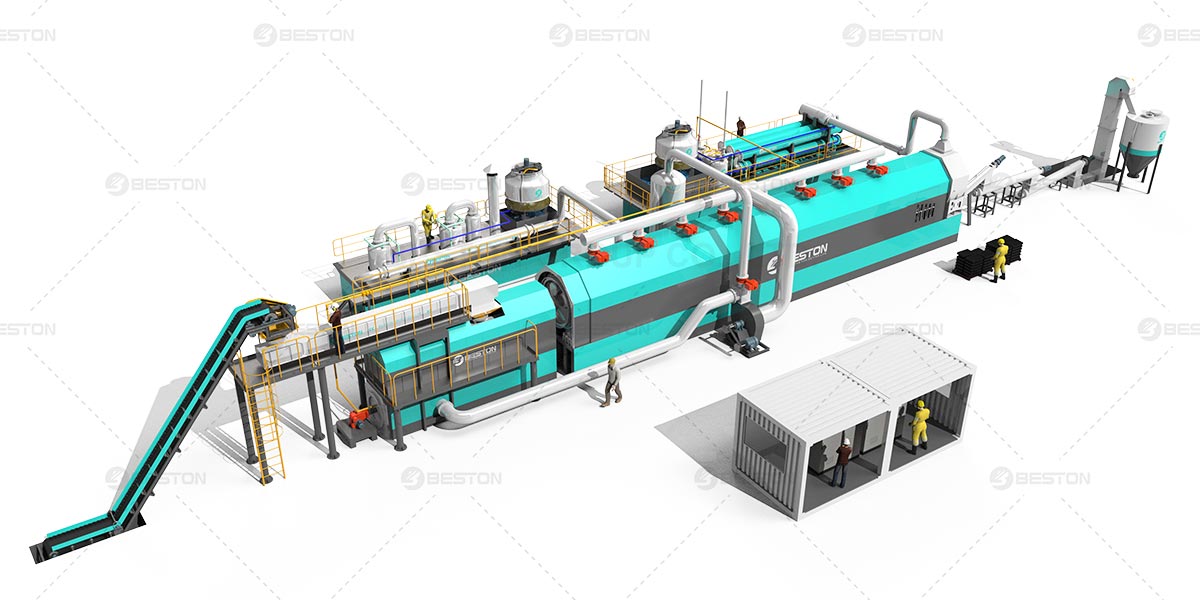

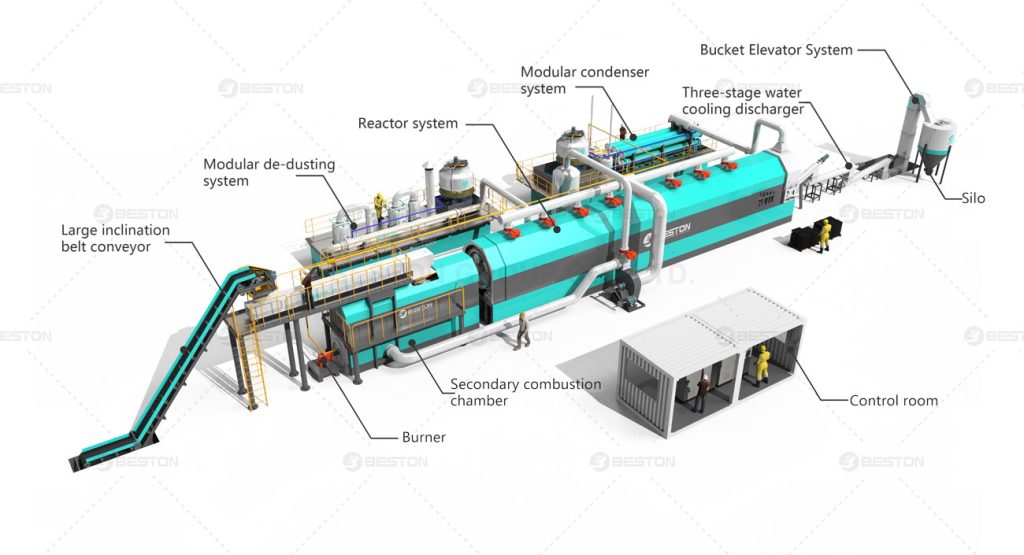

At the nucleus of the pyrolysis revolution lies the enigmatic plastic pyrolysis machine, a technological marvel designed to metamorphose discarded plastics into a liquid goldmine—oil. Plastics, notorious for their environmental persistence, find redemption in the intense heat and absence of oxygen within these plants.

The symphony begins as plastics, ranging from ubiquitous polyethylene to resilient polypropylene, undergo thermal degradation. The controlled environment of the plastic pyrolysis plant orchestrates the breakdown of polymer chains into a volatile concoction of hydrocarbons. Through meticulous condensation, this vapor transforms into a liquid, resembling a crude oil distillate rich in potential.

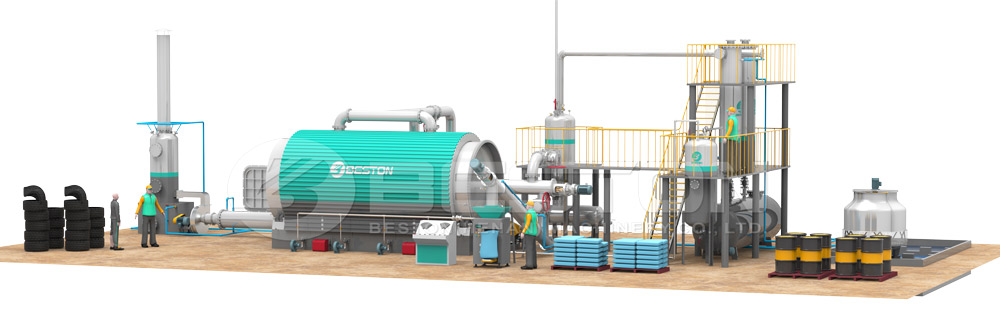

Tyre Pyrolysis Plant: Reinventing the Wheel of Sustainability

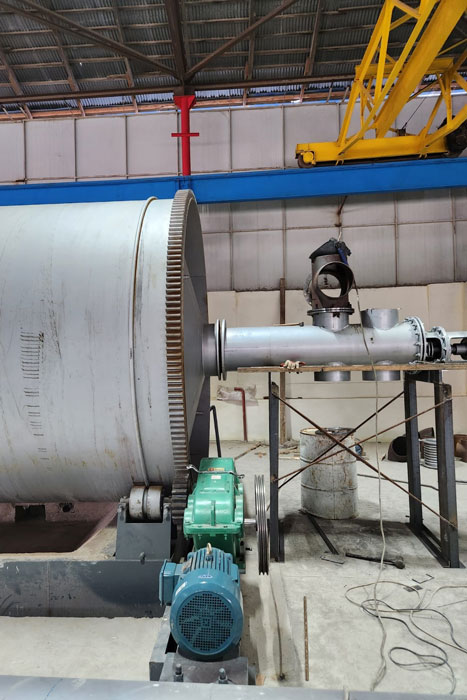

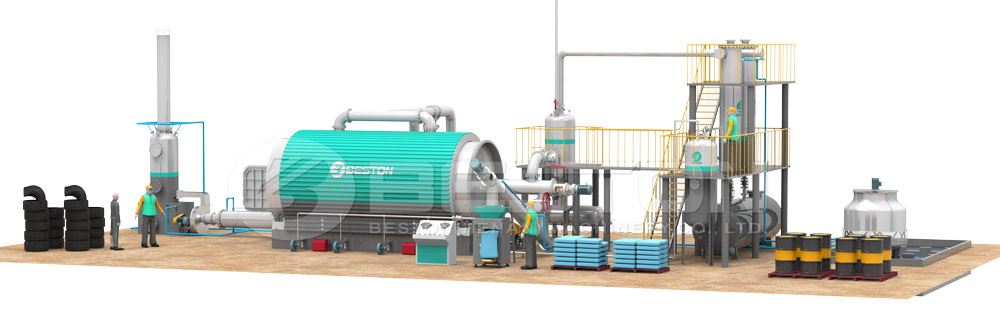

As we shift our focus from plastics to the rubber domain, the tyre pyrolysis plant takes center stage. Discarded tires, a ubiquitous byproduct of our vehicular culture, metamorphose from environmental liabilities to renewable resources within the confines of this specialized pyrolysis apparatus.

Tires, composed of complex rubber compounds and steel reinforcements, undergo a transformative journey. The intense heat of the tyre pyrolysis plant prompts the rubber to decompose, releasing valuable hydrocarbons. Moreover, the steel reinforcements, liberated from their rubber encasings, emerge as recyclable byproducts. Thus, through pyrolysis, discarded tires find a second life as fuel and reusable materials.

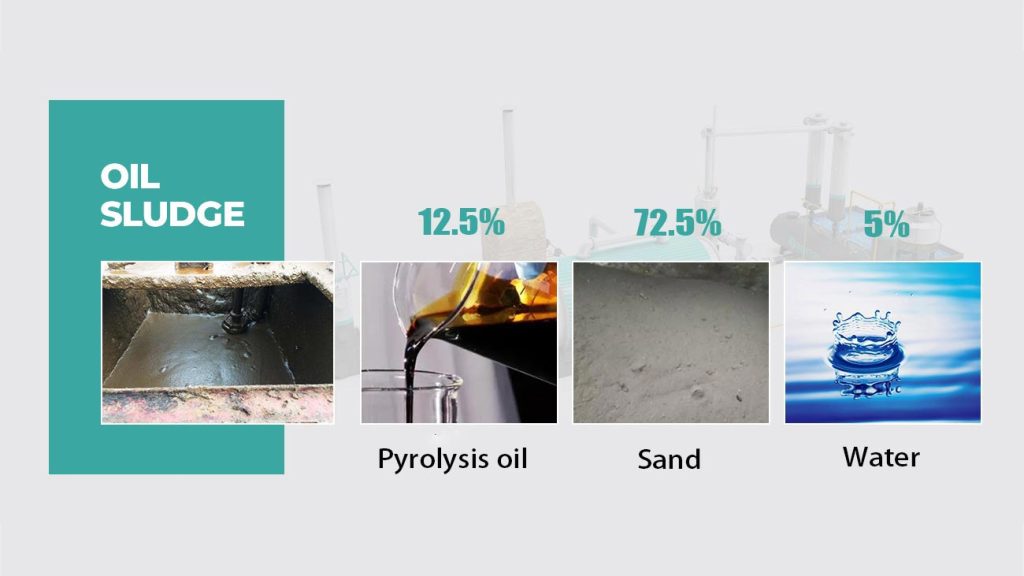

Oil Sludge Pyrolysis Plant: Tackling Environmental Quagmires

Amidst the quagmire of oil production, oil sludge pyrolysis plant emerges as eco-saviors, addressing the environmental aftermath of oil extraction. Oil sludge, a byproduct laden with hydrocarbons, heavy metals, and contaminants, transforms from a liability to a resource through the intricate dance of pyrolysis.

The process unfolds as oil sludge, replete with complex compounds, is subjected to high temperatures within the pyrolysis plant. The heat triggers the disintegration of organic components, liberating hydrocarbons that condense into valuable oil. Simultaneously, the plant captures and addresses environmental contaminants, providing a dual-edged solution to the oil industry’s environmental conundrums.

Rubber Pyrolysis Plant: Breathing New Life into Elasticity

Venturing into the realm of synthetic rubber, the rubber pyrolysis plant exemplifies the circular economy’s ethos, offering a sustainable alternative to the end-of-life fate of rubber products. Discarded rubber items, from conveyor belts to industrial seals, find rejuvenation through the transformative powers of pyrolysis.

The rubber pyrolysis plant subjects rubber products to intense heat, prompting the breakdown of polymer chains into valuable hydrocarbons. This resultant liquid, akin to crude oil, becomes a versatile raw material for fuel production. In this way, synthetic rubber products, once condemned to landfills, become valuable contributors to the energy landscape.