Biochar is a type of charcoal that is produced from waste materials. Sawdust, rice husks, and coconut shells are just a few of the many materials that can be converted into biochar. There is significant demand for biochar, which is why now is the ideal time to invest in biochar production equipment.

Biochar Has Many Benefits

Biochar is an environmentally friendly alternative to the organic materials used in many industries. It’s affordable to produce, and it has a wide range of applications, making it highly versatile. Biochar can also be found in many forms, including pellets and ash.

Biochar has a positive impact on the environment, and it’s an excellent alternative to charcoal and other materials used across different industries. When you look at the many advantages that biochar can offer, you’ll quickly see that it’s more than worthwhile to invest in biomass equipment. As the environment becomes a larger concern, it’s likely that the demand for biochar will grow. Click here to know more about Beston Group.

Another major advantage of biochar is the impact that it has on the environment. Biochar is considered to be carbon negative, which means that it can actually reduce the amount of carbon dioxide that is in the atmosphere.

Biomass equipment can help you to reduce your carbon footprint. This is also one of the reasons that biochar is sought after in so many industries. Using biochar can be a way for businesses to offset the carbon that they are producing.

There Are Many Types Of Equipment On The Market

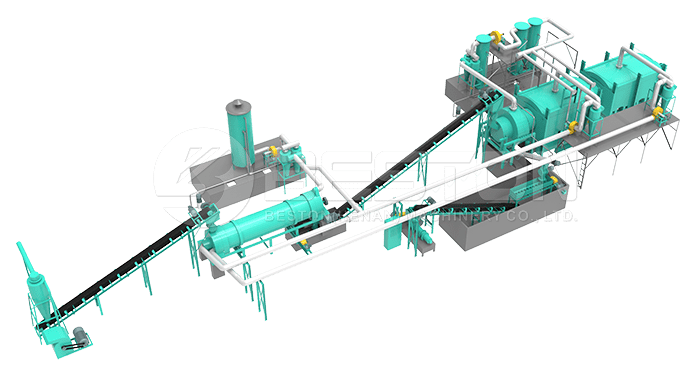

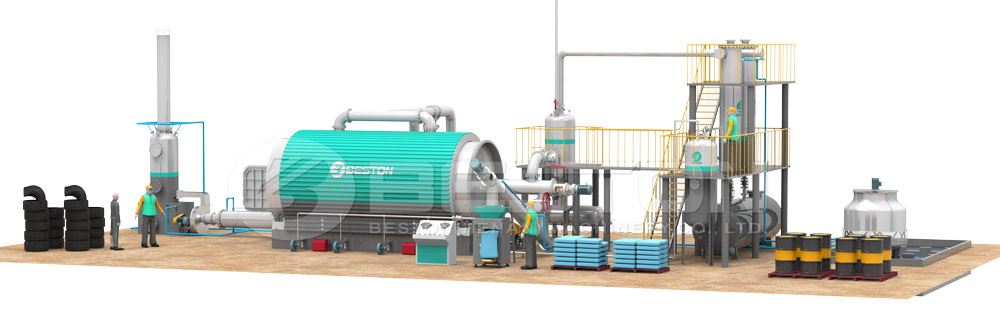

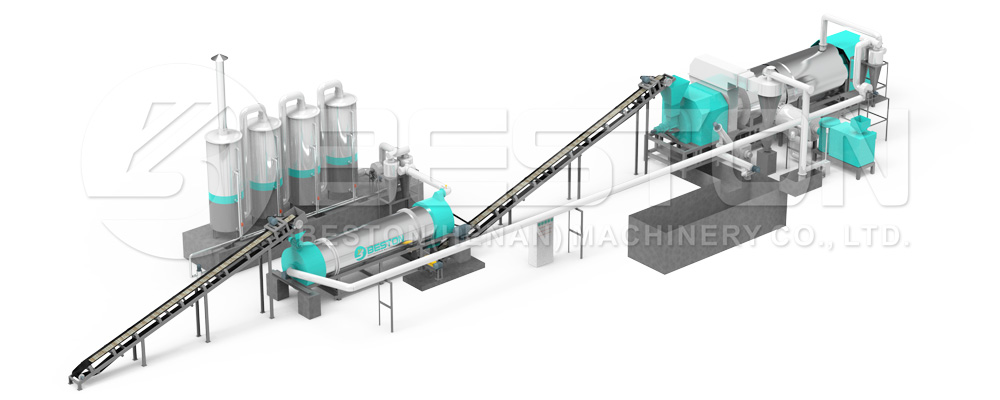

When you do invest in your production equipment, you won’t be at all limited in your options. There are many types of charcoal making machines on the market. Many biomass machines are designed to be used with a specific waste material, such as rice husks. Some machines are small and compact, while others are larger.

A fully continuous biomass pyrolysis plant could be the right choice for you, but you may find that it’s better to invest in semi-automatic equipment. No matter what you choose to do, you’ll be able to explore a number of options and make a decision that you feel confident about.

You’ll Be Able To Recoup The Cost Of Investment

Typically, biochar equipment is designed to be energy efficient, which means it doesn’t cost a lot of money to operate. Furthermore, you’ll be able to convert waste materials into a valuable material that can be sold to others, which means the potential for profit is high.

Because the initial purchase price of this equipment can be high, it’s important to know that you’ll be getting your money’s worth. After investing in this equipment, you’ll be able to produce valuable goods right away, which means it won’t take long to see a return on your investment.

There are a number of excellent reasons to invest in biochar production equipment. Now is the ideal time to find out more about the charcoal making machine on the market today. Explore your options and find machinery that you’d be happy to invest in.